Table of Contents

Chemistry Clash: How the Inks Actually Work

Sublimation Ink 101: The Science of Dye Gas

DTF Ink: Pigment-Based and Built to Stick

What Happens When You Mix the Two?

Testing the Myth: Real-Life Trials & Results

Case Study 1: Sublimation Ink on Sublimation Paper

Case Study 2: Sublimation Ink on DTF Film

Case Study 3: DTF Ink on DTF Film

Insights from the Experts

Hidden Costs of Cutting Corners

The Cost of Reprinting and Wasted Materials

Unhappy Customers = Damaged Reputation

Putting Your Printer’s Health at Risk

Better Alternatives to Hybrid Hacking

A. Stay within Your Lane–Make the Most Out of Your Sublimation Setup

B. Want To Print On Cotton Or Dark Garments?

C. For Low-Volume Jobs: Heat Transfer Vinyl (HTV) Is Still King

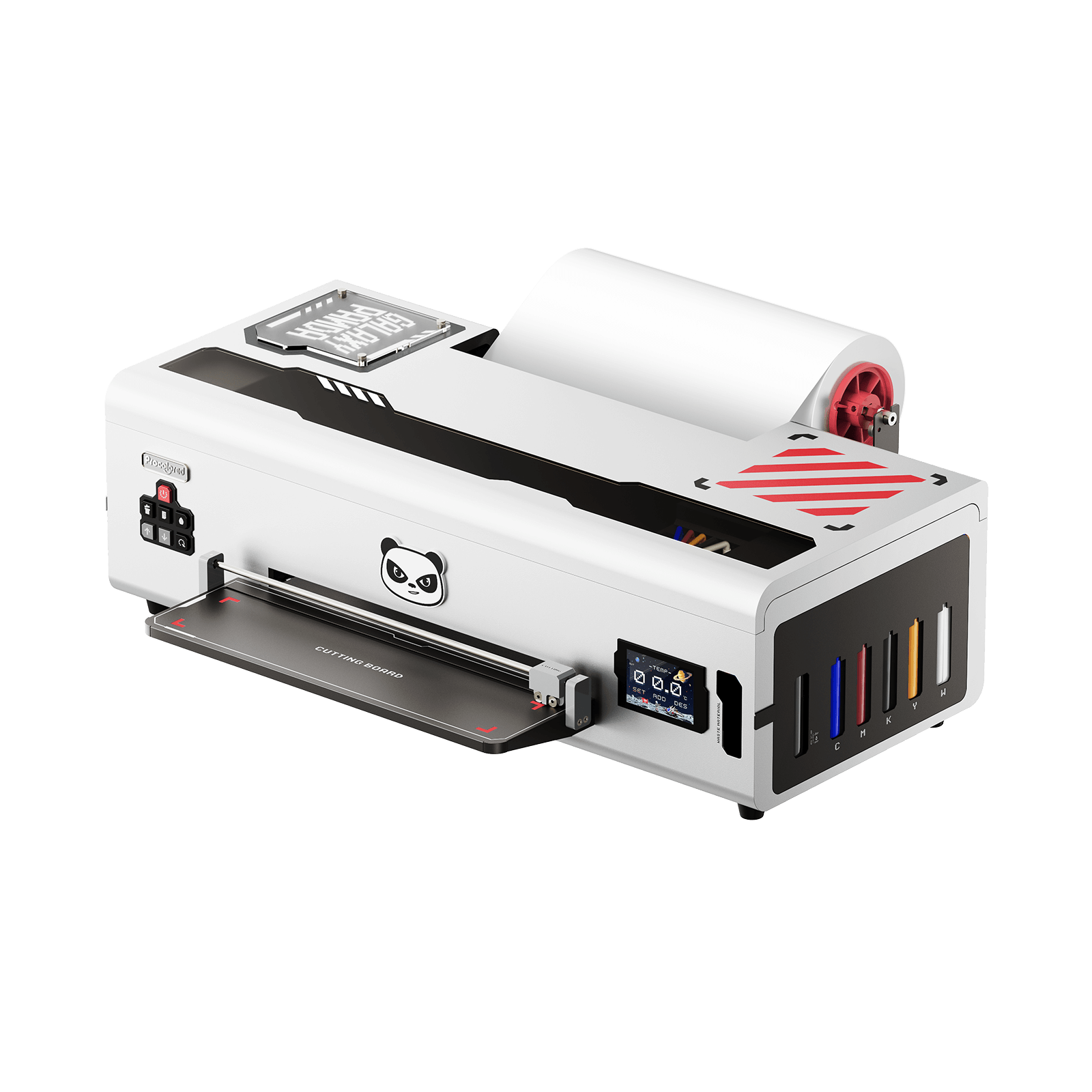

D. What About Those Printer “Hybrid” Claims?

E. Be Real: Grab the Right Tool and Spare Yourself the Headache

Conclusion: One Ink, One Mission

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!