Got a brand new printer together with endless problems?

Noticed your frustrated concern but we have to point it out : most printers per se are really good, only if you do regular and proper maintenance. Read our passage below to get more information about printer maintenance!

PASSAGE SUMMARY

1. What a Printer (Machine) Really is

A lot of devices have been invented on human history to help surpass the limit of human body and human force. And with development of modern technology and electronic constructions, devices or machines nowadays are more about complex systems combining structural elements, mechanisms or control components for convenient use.

Printer, as one kind of output machine that interprets and presents graphics or text from computing devices to paper (in most cases), is also designed as an integration of various advanced systems and functionalities. To be more specific, it’s equipped with complex and innovative technologies mainly including but not limiting to:

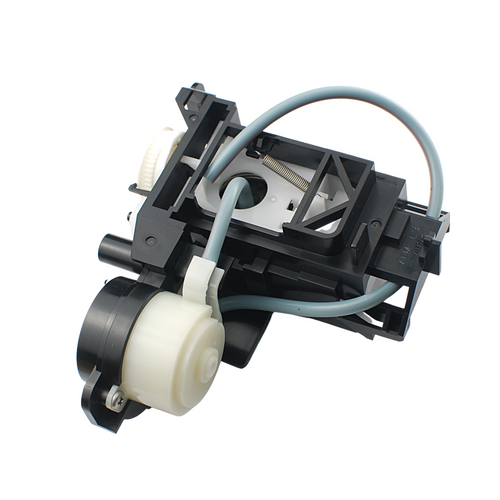

Precision engineering - Yes, nozzles eject inks onto paper, most people know that, but it’s not the only ruler of the printing game. To proceed a precise and successful printing, other components are also needed and essential: motors to initiate all activities, feeder to move paper timely and precisely, and other numerous ones processing complex algorithms.

Electronics and microcontroller systems - Most printers are powered by electricity, which means the intricate circuitry and microcontrollers inside a printer are the exact energy supply that enables processing of data, management of printing task or en even control of heating elements.

Software integration and network connectivity - More and more printers nowadays are equipped with devices and settings supporting wider applications, via software integration and network connectivity. The former one allows printers to share information and data with software functioning like image processing or cloud storage; the latter one provides network support for the software integration and data sharing.

Security features - Two main concerns here: one is data disclosure due to network connectivity and one is energy leakage due to electricity appliance. To better protect the safety of both machine per se and the user, most printers nowadays are equipped with data encryption systems, as well as protective devices achieving machine insulation, over-voltage protection, temperature monitoring, etc.

2. The most frequently seen printer issues

As we’ve pointed it out, a printer is complicated integration of numerous components, only when they are all in good and proper conditions can a printer performs smoothly as it’s expected.

But there’s always a catch in life - tainted ink color, click-clacking sound, or red lights on the printer flashing for reasons that you may never know. So what on earth is going on with these printers when they are supposed to be smart?

A well-functioning printer is resulted from successful teamwork of all the components. Any malfunctioning of any part might lead to machine issues that stop a printer from working.

Below issues are the most common ones according to our users’ feedback.

Clogged nozzles - Nozzles are super tiny holes located on print head, and they are the exact places where ink are deposited. Dried ink, ink debris, tiny foreign dust can easily clog them and cause failure in printing.

Dried ink - This is most commonly seen on printers idle for quite a long time. When a printer is left unused, inks in cartridges will gradually stand and evaporate, leading to dried ink that hampers smooth printing.

Print medium jams - Paper or film, vinyl sheet or toner sheet, no matter which kind the print medium is, it can easily get stuck in the paper path due to its poor quality, wrinkled surface or foreign objects ahead.

Misaligned configuration - To achieve high quality printing, a printer must be set and calibrated in different parameters, including color space, print head alignment, temperature and humidity, etc. Misalignment of them might lead to less satisfactory printing outputs with potential quality issues.

Loud operating noise - Abrasive encoder strip, hindered drive belt, or loosen printer components can lead to loud and unexpected noise during the printer operation. Hardware are tough fellows that need gentle care.

3. How to Perform Regular and EFFECTIVE Maintenance

Most issues mentioned above frankly can be avoided if regular and proper maintenance has been performed.

Corresponding to above problems, Procolored herein provides maintenance suggestions as below:

3.1 Maximize printer usage

We highly recommend to use your printer as often as possible. An often applying of printer can effectively improve the stability and dynamic of inks and help reduce accumulated dust on the moving components.

But if you indeed don’t have that much printing plans, or if you’re about to have a vacation away, it’s strongly suggested to apply moisturizing devices on your printer.

Check below to see how moisturizing devices work exactly.

3.2 Perform regular cleaning

As it’s mentioned above, ink buildups or foreign objects sometimes may lead to nozzle clogging or printing medium jams, that makes regular machine checking and cleaning essential.

The first cleaning to be done should be ink debris cleaning - near ink cartridges, on print head nozzles, around capping stations or wiper blade, these are the places more likely to accumulate ink debris but several takeaways should be born in mind during their cleaning:

Always use lint-free swabs or cloth to do the cleaning - An effective cleaning should guarantee both neatness and good working status. Lint-free materials can remove ink buildups with fewer new foreign dust or objects left.

Apply alcohol to do the cleaning -Alcohol is recommended for printer cleaning as it owns higher cleaning efficiency and lower damage possibility. Using alcohol to do the cleaning can effectively reduce cleaning time and prevent printer components from over-moisturized.

Some printer components are alcohol-intolerant - Yes alcohol are perfect cleaning agent since it evaporates fast but this is the same reason why it can’t be used on print head bottom - where nozzles are located, and capping station - which directly touches nozzles. With fast evaporation of alcohol on the component surface, the left ink debris will get dried quicker and cause clogging issues. We highly recommend to apply moisturizing cleanser to clean these two special places.

3.3 Practise regular calibration

Color space, print head alignment, temperature, humidity and so forth parameters, can be calibrated and adjusted via testings from time to time. It’s true that parameter performance can only be censored through real printing outputs, but we highly recommend to use graphics of relatively small size as testing subjects to reduce ink and paper/film consumption.

3.4 Hardware maintenance is also important

Hardware in a printer typically refers to drive belt, encoder strip and other printer components. They are places less possible to get ink debris on but still, specific maintenance should be applied correspondingly.

Regular cleaning is a must do on them. Regular cleanings can effectively and timely get your printer away from accumulated dust and foreign objects. The only key point to remember is that all the cleaning must be done gently and any disassembly of parts your know or not know is abusolutely not recommended.

Besides cleaning, some components also need extra special care. Take encoder strip for example. Encoder strip needs lubricating oil supplement periodically so that it can run smoothly to conduct nozzle moving, or a printing task might be stopped the moment it begins.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

About the Author - Simon

Simon has worked in inkjet printing industry for years. He has the rare ability to see print related issues from many perspectives. Witnessing the gradual development of digital printing especially inkjet printing, Simon knows better about what the users are looking for and how the new technologies will truly help big or small businesses.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!