Impresora UV

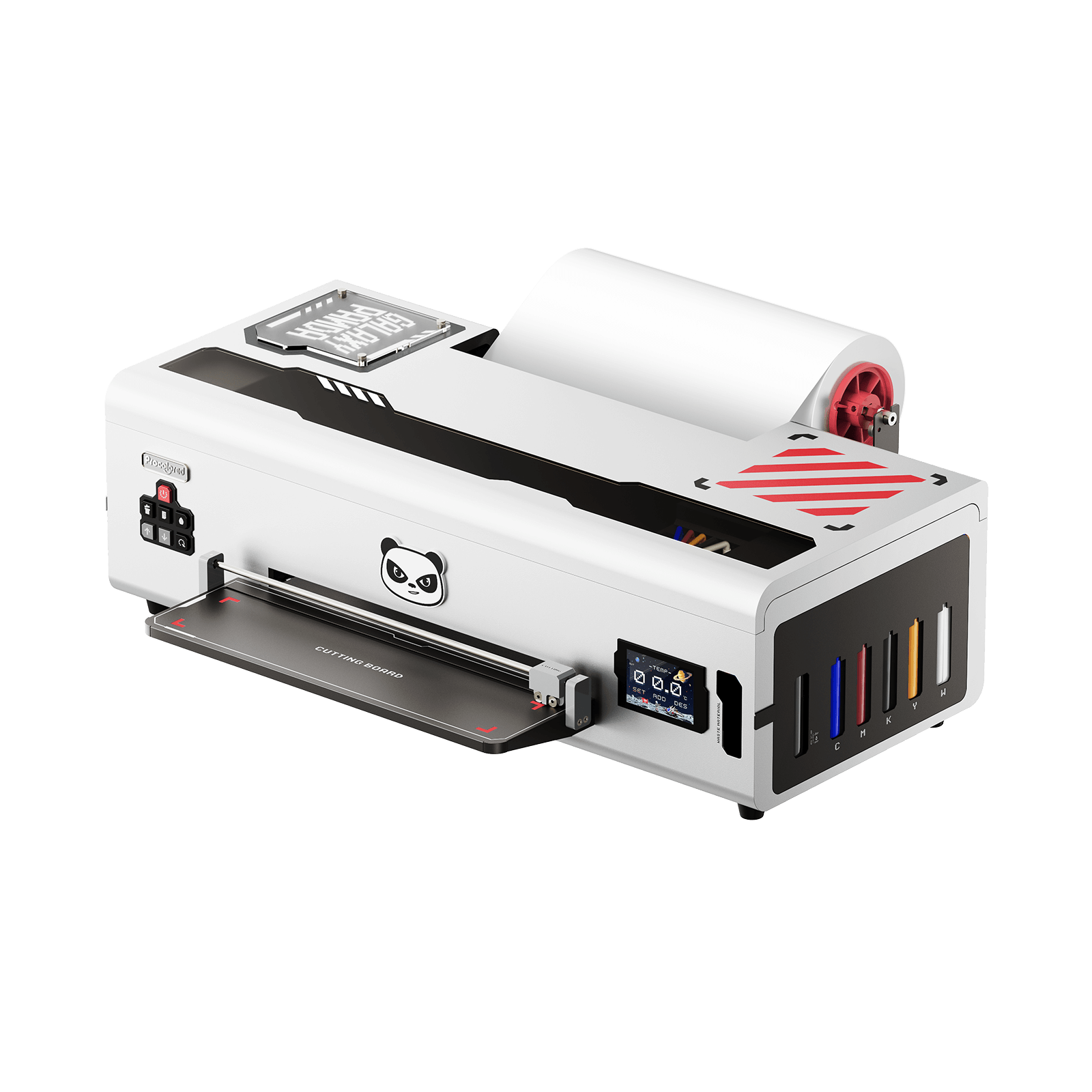

UV printerTambién conocido como impresora Ultra-Violet, aplica tinta UV y luces UV integradas para lograr impresiones directamente en superficies de madera, metal, acrílico, cristal, vidrio y otros materiales.

Procolored ofrece impresoras UV de diversos tamaños para diferentes necesidades: impresora UV A4 y A3 para impresión de decoraciones, incluyendo placas de madera o fundas de teléfono; impresora UV A1 para impresión de letreros de jardín o tableros publicitarios.

Embárcate en tu viaje de creación con una impresora UV Procolored ahora, o compara nuestras máquinas primero para una toma de decisiones más informada.

Filtrar

4 productos

Collection

Impresión UV

La impresora UV utiliza luces ultravioleta para curar las tintas una vez que se imprimen sobre diversas superficies de cama plana, incluyendo papel, bloques de madera, botellas de vidrio y otros artículos y materiales. Las tintas UV especiales que se imprimen en las superficies se secan casi al instante cuando se exponen a la luz UV. La impresora puede imprimir sobre superficies no absorbentes y producir impresiones de alta calidad y duraderas. La imagen impresa es vibrante, de alta resolución y resistente al desgaste. Procolored ofrece impresoras UV en varios tamaños y configuraciones, desde A5, adecuado para la impresión de fundas de teléfono, hasta grandes impresoras A3 plus de escala industrial utilizadas para la producción en masa.

For printings on hard substrates, we also recommend UV DTF printer.

Aplicación

La impresión UV se aplica comúnmente para producir letreros, pancartas, fotografías duraderas y artículos promocionales que pueden usarse en la decoración y el branding de productos. En términos generales, no se recomienda aplicar impresión UV en prendas de vestir, excepto en cuero o ropa de paraguas, ya que no absorben las tintas y no están en contacto directo con la piel.

Impresión UV sobre madera

La madera, de hecho, es bastante común en nuestra vida diaria, desde pequeños bloques de madera como los de Scrabble, cajas o estuches de madera, hasta objetos más grandes como instrumentos, monopatines o muebles. Como método de impresión por inyección de tinta, las impresoras UV de cama plana transfieren la imagen a la madera con mayor precisión; además, la impresión sobre madera suele ser más vibrante y duradera. ¿Estás pensando en iniciar un pequeño negocio de impresión UV? Las impresiones en madera pueden ser tu primera opción absoluta; actúa ahora para sorprender a tus clientes imprimiendo bloques o placas de madera.

Impresión UV en funda para teléfono

La personalización de fundas para teléfonos es otro negocio popular relacionado con la impresión UV. Una ventaja clave de aplicar la impresión UV en este negocio es que puede producir fundas con diferentes gráficos a la vez: todo lo que debe hacer es reunir los gráficos deseados en una sola imagen y organizarlos en un diseño específico. Esto le permite fabricar o vender fundas para teléfonos con una gran variedad de patrones.