Before we get into the DTF printing, let’s compare different methods of printing. In this video, we are not talking about dye sublimation printer or flatbed UV printer because they are not popular for T-shirt printing now.

Screen printing uses a mesh screen to transfer inks onto T-shirt. It is a good method to print one design quickly on a large scale. If you just start up a small business, it’s kind of difficult to sell dozens or hundred of T-shirt of the same design. You’ll spend quite a lot time to get the mesh screen ready just to print 2 or 3 T-shirts. So screen printing is not practical for selling one-offs.

Embroidery machine has multiple needles sewing threads on fabric and materials. To digitize a file for embroidery machines, you must be good at using software to choose the direction of the threads and colors. This job is very different from T-shirt design. For a beginner, it can be a difficult learning curve.

Heat transfer is a great method to start with a low budget. You can simply cut some texts or icons using a vinyl cutter and imprint the design onto the T-shirt. It’s usually used for a text based design and pretty much just a single color.

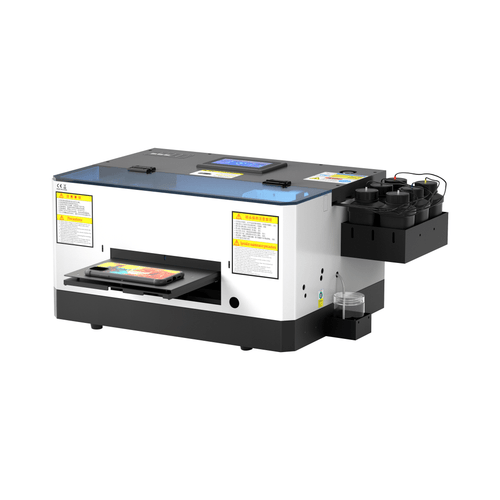

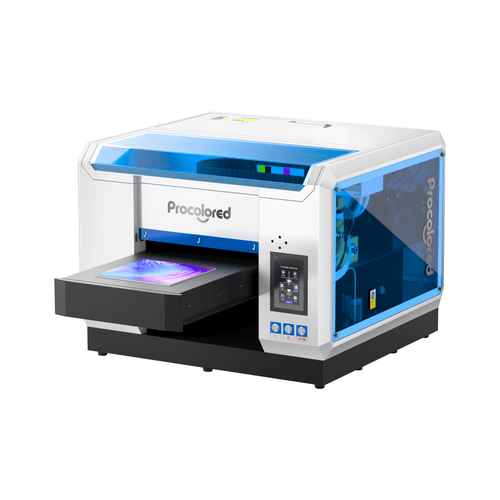

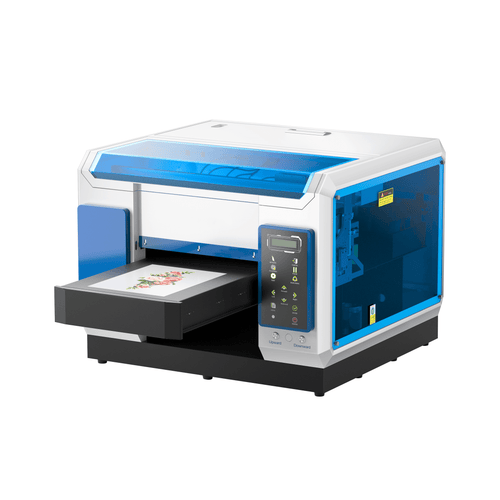

Direct-to-Garment is suitable for small business. It great for one-off full color prints with a soft hand feel but can only be applied on clothes which contains more than 80% of cotton. Materials like linen, nylon, polyester or PU can not be used. The printer should be used frequently to avoid ink clogging. The nozzle issues can cause a high maintenance fee.

DTF Printer is most popular used in T-shirt Print-on-demand business. Compared to DTG printer, the nozzle of DTF printer is less likely to lead to ink clogging issues and creates more vivid colors. Learn more about how to make dtf transfers at home.

I always be asked a lot that how much does it cost to run a DTF heat transfer printer. So the next thing we are talking about is how to estimate the cost of DTF T-shirt printing.

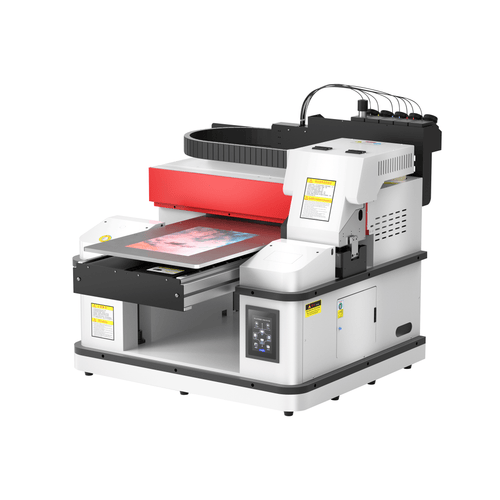

In the process of DTF printing, we need consumables like inks, printing film and DTF adhesive powder; and we need equipment including curing oven, heat press and DTF printer. We don’t take processor software for account, because we offer RIP software for free.

The amount of print achievable with 1000ml of ink depends on the image size. Here we will estimate the printing cost based on size of an A4 sheet. Using 1000ml ink, it’s possible to print 200 to 500 T-shirts, which means the average ink consumption of one T-shirt is 2.5ml. The typical price of decent DTF ink is 10ml per dollar. So we get the cost of ink for one shirt is 0.25 dollars. 100 pieces of printing film cost 70 dollars, equivalent to 0.7 dollar per sheet. 1000g DTF adhesive powder cost 100 dollars. The powder is very lightweight and about 1.5g is required for one shirt. If you buy a bag of 1000g powder, it will be enough for about 666 T-shirts, and that’s only 0.15 dollar per shirt.

So far, the total cost we have listed adds up to a printing cost of $1.1 per shirt.

In order to estimate the cost of equipment evenly spread across each shirt, we need to take into consideration the lifespan of the equipment. Although these pieces of hardware can be used for several years, we need to calculate the cost based on the lifespan of our business rather than the lifespan of the equipment itself. Equipment costs will be apportioned over all T-shirts printed during the business lifespan. Let’s assume that we want to make profit from the first year and sell 50 shirts per week, then we calculate the printing cost base on these conditions.

On our website, the complete bundle of an A4 DTF printer cost around 3000 dollars, which includes an A4 printer with single printing head, a curing oven, a heat press and an air filter. There are 52 weeks in a year, so we average the price of the DTF transfer printer bundle over 52 weeks, which comes out to $57.69 per week. Then we allocate the weekly printer cost evenly among the 50 shirts, resulting in an equipment cost of $1.15 per shirt. But is this the final cost? No, we also need to consider the cost of maintenance in case of equipment failure. For example, the printer head may become clogged due to lack of cleaning or long-term idle. We can usually solve this problem with the direct to film printer's "flush" function, but sometimes the problem cannot be resolved, and we need to replace a new print head. The price of the print head is $320, assuming that we need to replace two print heads in a year, which comes out to a maintenance cost of $0.25 per shirt.

We add up the machine-related costs, resulting in an equipment cost of $1.4 per shirt, which is evenly distributed among the shirts.

The third cost comes from the blank shirt. On Alibaba or other wholesale websites, a shirt that meets quality requirements costs around 3 dollars. Depending on the quality requirements, the price of the shirt varies. We need to contact suppliers about the quality and price before order.

Therefore, ideally, a printed shirt, including printing costs, equipment costs, and fabric costs, costs a total of $5.5. We also need to set a 20% waste rate for the final cost because we may produce defective products during the printing process, or waste shirts or ink due to various reasons. Finally, the actual cost per shirt is $6.6 when the T-shirts come up to the market.

Before doing the Print-on-demand shirt business, we need to investigate and confirm our target audience, determining the age range clearly and streamlining the color and style options, because too many options mean more inventory and costs. We need to make customers focus on our design rather than hesitate between styles and colors. Limiting options make our business more successful. Shirt printing is a very broad market with enough space to accommodate all of us creative business persons.