Discover the new tendency - UV printing

Custom phone cases, bespoke notebooks, personalized bottles - more and more people now are asking for possessions or presents designed with personal marks, prospering customization-related businesses. Wanna be a creator of such new trend or wanna learn how can that be achievable? Scroll down to learn more.

PASSAGE SUMMARY

1. What is UV Printing and How Does it Work

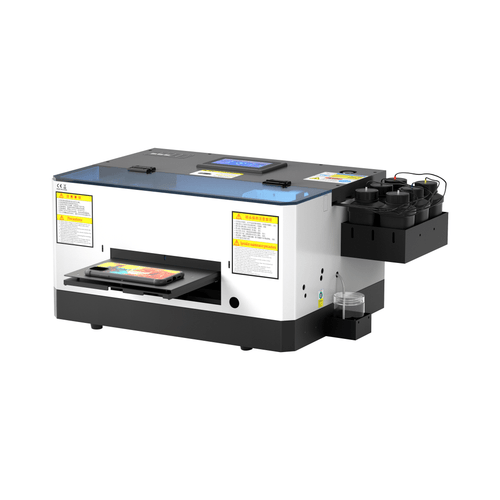

UV printing is a novel kind of digital printing that allows inks directly printed on substrate surfaces. To support such function, UV printers normally are equipped with built-in printing platform and UV lights, providing a stable workbench and instant curing for the printed inks.

UV printing can be processed with or without varnish ink, but UV inks are a must for the printing. To finish a UV printing process, the prepared object (of appropriate height) must be put on the printing platform to receive direct ink spraying. Right after the printing, the built-in UV lights will trigger a chain reaction within UV inks and cure them into a solid, bonded film on the substrate.

2. Why UV Printing is On the Rise

UV printing can not be used on fabrics as DTF printing, instead, it can be used on lots of other materials including paper, glass, acrylic, crystal, metal and so forth, presenting below main advantages:

Durability - UV inks are cured with strong bonding as it’s mentioned above, and such chemical reaction has greatly heightened the durability of UV printing, protecting UV printings from damage caused by sunlight, water or any scratching.

Instant processing - The built-in UV lights provide instant curing for the printed UV inks, and greatly shorten the entire processing time, promising an absolute advantage of UV printing compared to other digital printings.

Outputs with vibrant and glossy colors - The higher pigment concentration, together with UV lights guaranteeing the instant curing before any ink bleeding or diffusion, both promise a perfect reproduction of UV inks during the printing. If varnish ink is also applied, the finished output will be modified with a more glossy finish that highly enhances the visual appeal and vibrancy of colors.

Eco-friendliness - Unlike most traditional printing methods, take screen printing for instance, UV printing won’t emit VOCs (volatile organic compounds) during the entire printing process, creating a more friendly and comfortable working environment.

With all these operational or environmental issues concerned, more and more people nowadays choose UV printing as a start of their small business, specializing in customized products like UV printings on phone case, wood or acrylic.

Phone case printing - Mobile phones are things people hold and bring around now everyday. To effectively highlight individual style and preferences, phone cases nowadays are requested to be not just protective but personalized.

UV printing can be applied on phone cases of diverse materials, including TPU, plastic, acrylic, glass, metal, aluminium, rubber and so forth. As a decoration part on phone case, it is capable of standing up to the rigors of use, providing a durable and long-time lifetime.

Printing on wood - Wood in fact is quite common to see in our daily lives, from wooden plates or small boxes, to bigger objects like instruments, skateboards or furniture.

As natural materials are becoming more and more popular, great number of people nowadays consider wooden products with natural grains as high-grade presents for their friends, family members or lovers.

Starting a wood prints business with UV printer now undoubtedly is one wise business choice. UV printing prints directly on wood surface without any pre-treatment or post-treatment needed, to the most extent protecting the original grain and presenting vibrant colors.

Acrylic printing - Acrylic, also known as PMMA (polymethyl methacrylate), is a versatile and durable material widely used for demonstrating and decorating.

UV printing on acrylic in fact is quite widely used in office or company construction. UV printing itself can achieve vivid presentation, and with the transparent and clear material trait of acrylic, the gloss and vibrancy of UV ink colors will be much more standing out and eye-catching, achieving emphasis on corporate logo, image or slogans.

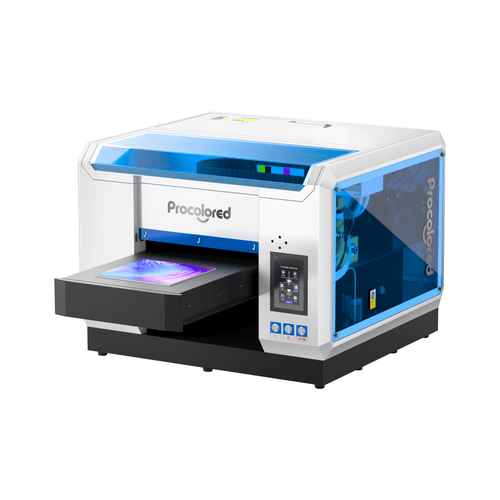

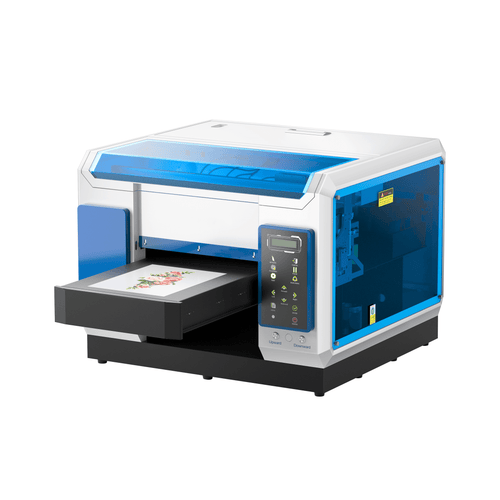

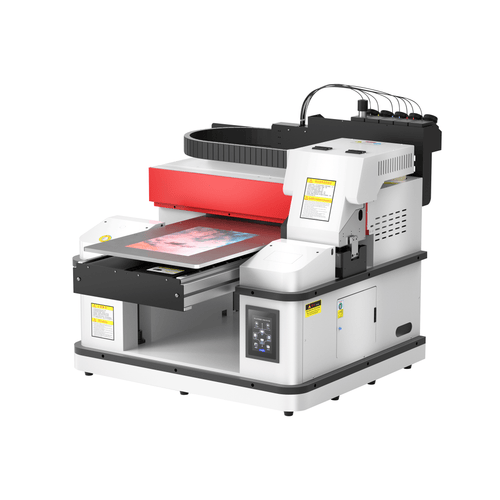

3. Meet Procolored UV Printers

Procolored has been in UV printing field since the day the company was founded. For all these years, Procolored has devoted itself to innovation and improvement of UV printing technology and user experiences, and has launched and presented a lot of related products with competitive features as below:

Multiple printable sizes - Procolored provides UV printers of different printable sizes from A4, A5 for desktop working to A3, A3+, A1 for bigger format printing.

Multiple print head configuration - Among all the Procolored UV printers, product# A3-Pro and A3+ 3360 are configured with two print heads and product# A1 6090 with three print heads. Multiple print heads greatly improve the printer’s working speed, making quicker and more instant UV printing possible.

Another takeaway of multi-heads is that the extra print heads normally is in charge of only one ink independently. Take the double-heads products mentioned above as example: the 6 cartridges of their second print head will independently be configured with white ink or varnish ink only. Through such specialized configuration, the white ink (as the entire printing base) or varnish ink (as the entire printing top) will be sprayed more quickly and accurately on the printing surface.

The relation between print head and cartridge of an UV printer can be summarized as below:

Print head number

Cartridge number

Cartridge layout

Single

6

CMYKWW

Double

12

CMYKWW+V*6

OR

CCMMYK+W*6

Three

18

CCMMYK+W*6+V*6

OR

CCMMYK+W*6+W*6

Automatic height adjustment - All Procolored UV printers are equipped with built-in Omron infrared sensor programmed with four-axis positioning system. The sensor will automatically adjust the printing platform height according to different prepared objects, providing instant protection to print head and other related printer components.

Advanced cooling system - Most Procolored UV printers are set with air-cooling and water-cooling system as well as a new thermal design, of which heat dissipation performance can be twice as efficient as its previous generation and of which running sound can be much lower.

Now UV printers also got their own PANDA!

Meet Procolored A4 UV Panda.

We’ve got quite numerous surprising feedback from our DTF printer users praising the panda appearance of the DTF printers. And in March of 2024, we finally brought the panda to Procolored UV printers!

Procolored A4 UV panda is an UV printer with appearance of panda animation design, together with all the mature UV printing technologies and configurations of Procolored. By providing this extra appearance choice, we sincerely hope to harvest more smiles from our beloved customers.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!