Table of Contents

Understanding the Basics of Sublimation vs. DTF Printing

A. What Is Sublimation Printing?

B. What Is DTF (Direct-to-Film) Printing?

Can You Use DTF Ink in a Sublimation Printer?

❌ Why It’s a Bad Idea

A. Ink Chemistry Clash

B. Print Head Pressure Problems

C. No White Ink = No Game-Changer Prints

D. Media Mismatch Madness

E. Goodbye Warranty, Hello Repair Bills

If You Want to Do DTF Printing — Go with the Right Tools

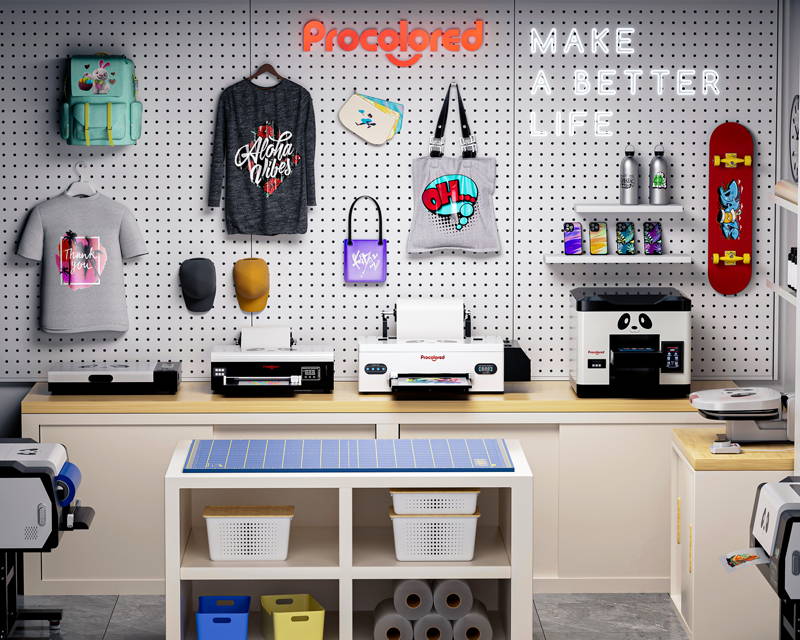

✅ Why Procolored DTF Printers Make Sense for B2C Users

⭐ Featured Picks: Procolored L805 & L1800 DTF Printers

Comparing Costs & Results

❌

❌

✅ Yes

What Happens If You Try DTF Ink In Sublimation Printer?

Who Benefits Most from Switching to a Real DTF Setup?

Conclusion: Don’t Risk It — Choose the Right Tool

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!