Frequently Asked Questions

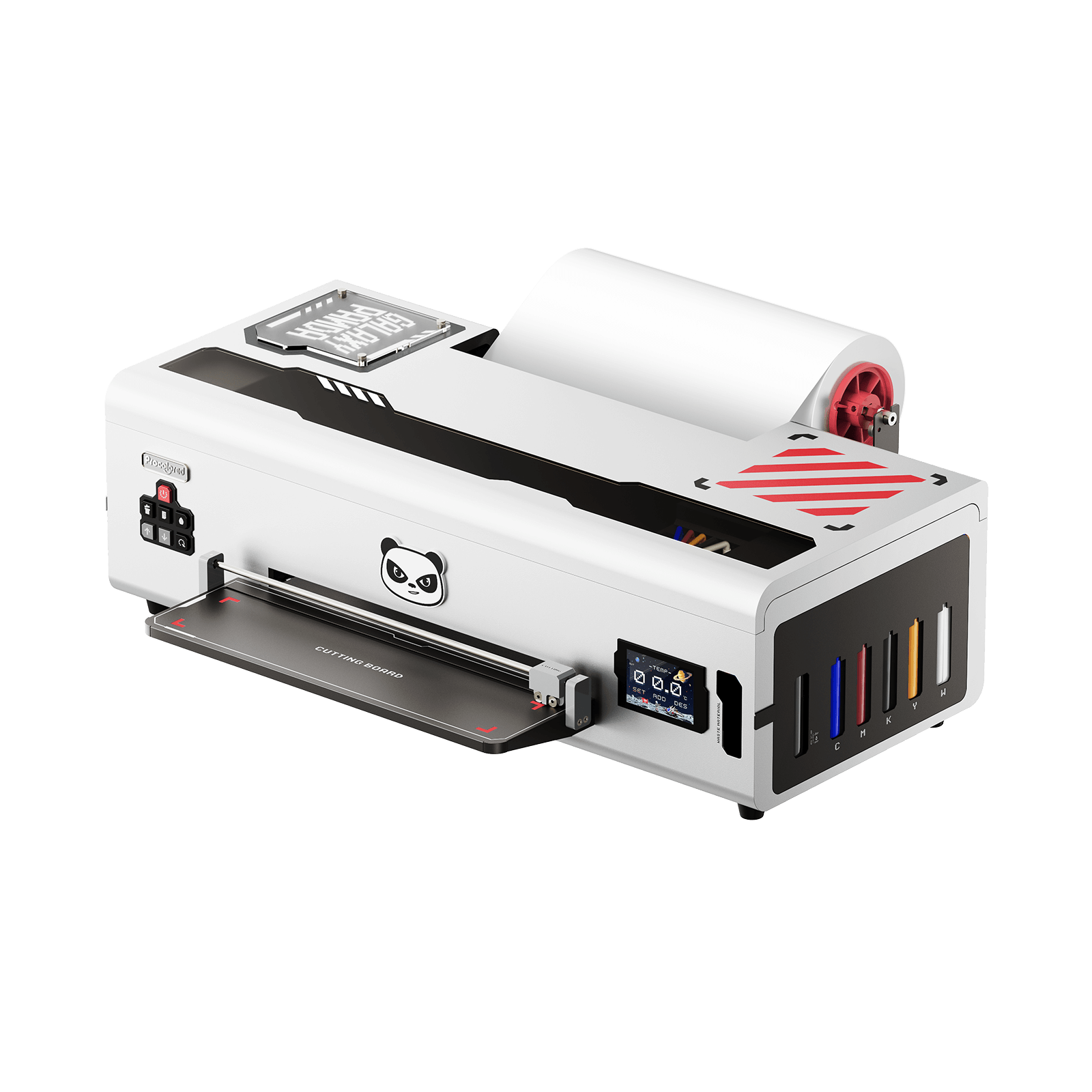

DTF consumables are used to print designs onto a special film, which is then heat-transferred onto fabrics such as T-shirts, hoodies, and other textiles.

DTF printing requires DTF ink, DTF film, and DTF powder. These consumables work together as a complete system.

No. DTF consumables are specifically designed for DTF printing and should not be used for UV, UV DTF, or DTG printers.It is 12 months.

Use matched consumables, store ink properly, and apply powder evenly to ensure stable transfers and long-lasting results.

UV consumables are used for printing directly onto rigid and hard surfaces such as acrylic, wood, metal, glass, plastic, and leather.

UV printing typically uses UV ink, UV varnish (gloss), and surface treatment liquid, depending on the material and finish required.

No. UV consumables are designed for rigid materials and are not suitable for fabric or garment printing.

UV DTF consumables are used to create transfer stickers and decals that can be applied to hard surfaces without heat pressing.

UV DTF printing requires UV DTF ink, UV DTF film, and UV varnish to produce durable peel-and-stick transfers.

UV DTF transfers can be applied to smooth, hard surfaces such as glass, metal, plastic, wood, and ceramics.

No. UV DTF consumables are designed for UV DTF workflows and should not be used in standard UV or DTF printers.

DTG consumables are used for direct-to-garment printing, where designs are printed directly onto cotton or cotton-blend fabrics.

DTG printing typically requires DTG ink and pretreatment solution to ensure proper ink adhesion and color vibrancy.