Table of Contents

The world of custom printing for clothes is very broad, as it has numerous techniques that can fulfill different requirements. DTF (Direct to Film) and vinyl printing are among the most popular methods of creating designs on clothes. Both have their unique advantages, but for business purposes, one must evaluate their differences, uses, and benefits prior to making a selection.

If you are new to the world of custom printing or if you are running a business that offers services in apparel customization, this guide will provide you with detailed information around DTF print and vinyl print, assisting you in determining the most aligned option for your requirements. Moreover, we will discuss which DTF printer is most suitable for your small business needs, along with comparing it to other methods such as sublimation printing.

What is DTF Printing?

DTF printing (Direct-to-Film) is the new way of digital printing wherein graphics are printed onto specially made PET film transfer sheets with eco-solvent or water-based ink. The design printed onto the film is dusted with adhesive powder and heated to bind the powder, after which it is pressed onto the fabric (cotton, polyester, or blends) or other materials using a heat press.

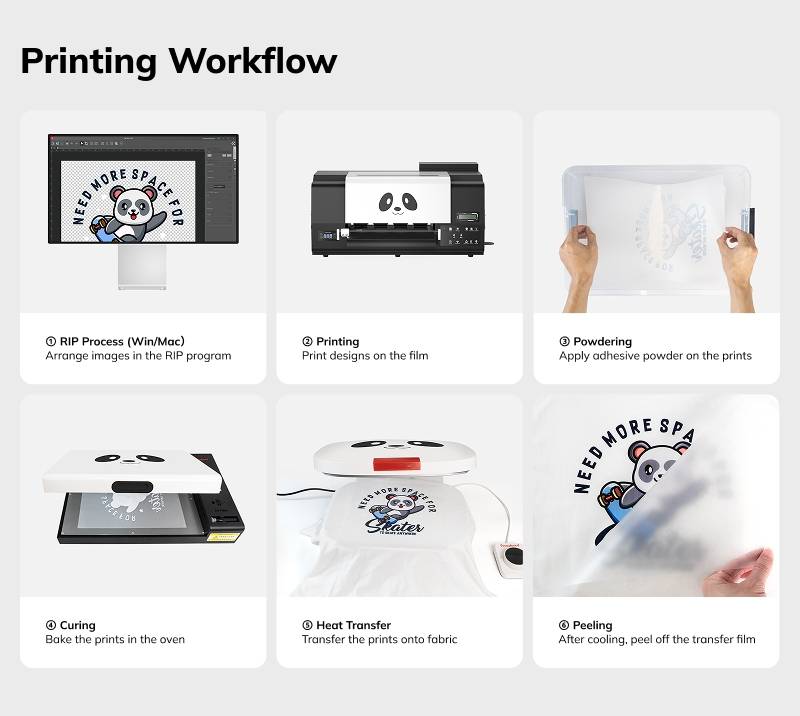

Step-by-Step DTF Printing Process

1. Design Preparation

Prepare graphic software (e.g., RIP software) to create or upload a design.

2. Printing on PET Film

Import the design into the DTF printer.

3. Applying Adhesive Powder

While the printed areas’ ink is still wet, apply a uniform layer of DTF adhesive power over the visible areas. Remove any excess powder to avoid clumping.

4. Curing the Powder

Keep the film in the curing oven for 2-3 minutes. This process melts the adhesive powder, attaching it to both the ink and the film.

5. Heat Press Transfer

Put the cured film (ink side facing down) on the fabric. With a heat press, apply medium pressure for 10-15 seconds, then peel the film away.

Key Benefits of DTF Printing

Versatility: DTF printing stands out due to its adaptable printing capabilities. DTF printing technology enables high-quality prints on multiple materials such as cotton and polyester blends while sublimation printing remains restricted to polyester and polymer-coated fabrics. The versatility of DTF printing enables the customization of a broad selection of apparel items including t-shirts, hoodies, and bags among others.

High-Quality Prints: DTF printing generates vibrant high-resolution prints which deliver perfect results for full-color designs along with detailed graphics and gradients. DTF printing stands out as the best option for producing custom logos as well as detailed portraits and complex artwork designs.

Durability: Durability makes DTF printing highly desirable because it maintains the print quality through multiple washes. The fabric maintains its print quality through multiple washes because the design remains soft and resists fading, cracking, and peeling after transfer.

Low Setup Costs: DTF printers are an affordable option for small business owners and newcomers entering the custom apparel market. The upfront expense of acquiring a DTF printing machine exceeds some competing methods but the reduced ongoing cost per print renders it a smart investment for businesses aiming to grow.

What Is the Best DTF Printer for Small Business?

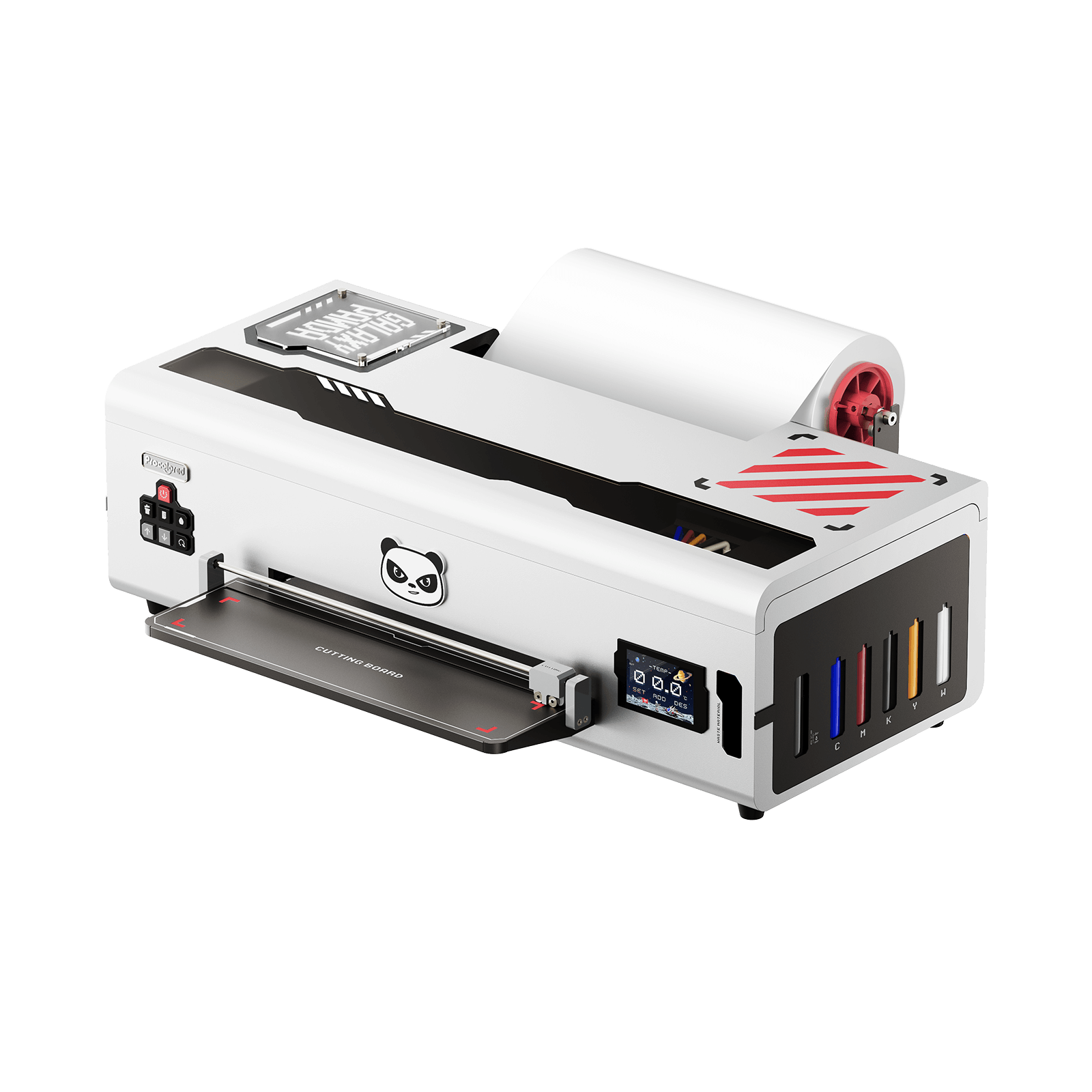

Choosing the correct printer remains essential whether you are new to DTF printing or operate a small business. The Procolored DTF printer stands out as an ideal choice for small businesses because it provides excellent print quality while remaining affordable and easy to operate. The A3 DTF printer stands out as an excellent option for users who need versatility to manage print runs of varying sizes. These printers deliver user-friendly operation and reliable performance making them ideal for adding custom designs to different types of fabrics.

What is Vinyl Printing?

Heat transfer vinyl (HTV) printing or vinyl printing for short, is widely used to produce custom designs on clothes.The process involves cutting out a design from a vinyl sheet using a vinyl cutter and then transferring it to fabric with the help of a heat press.

Key Benefits of Vinyl Printing

Durability: It is no secret that vinyl printing comes with excellent durability. It does not matter how many times the garment is washed, vinyl prints will not peel, crack, or fade. Because of this reason, sports jerseys, custom t-shirts, and other frequently worn clothes will benefit from vinyl printing.

Simple Designs: Simple and bold designs are best suited for silhouette or text art, and logos. For t-shirts with names or logos printed in a single color, there is no better choice than vinyl printing due to its speed and competitive pricing.

Tactile Feel: Vinyl prints provide a raised texture as opposed to DTF printing which offers a smooth and soft touch to the fabric. The dimensional feel brought about by the raised texture enhances the design. Many customers love this tactile sensation especially for sports numbers or team names.

Wide Range of Finishes: In addition to matte and gloss, vinyl also comes in glitter and metallic finishes which allows for the production of vinyl designs that are striking and sophisticated from variety of already existing designs. Complex looking designs can also be created by mixing different colors and textures of vinyl.

Vinyl Printing for Beginners

New users will benefit from learning vinyl printing as it is one of the easier types of custom printing. Using a vinyl cutter and heat press is straightforward, and the process is less involved than DTF printing. For small businesses, particularly those that specialize in basic logos or text, vinyl printing is highly beneficial.

DTF Printing vs Vinyl Printing: A Side-by-Side Comparison

DTF Printing vs Vinyl Printing: A Side-by-Side Comparison

1. Print Quality and Detail

DTF printing: DTF printing has an advantage when it comes to multi-colored designs with lots of depth and detail. DTF prints are perfect if you wish to have intricately designed artwork, full-color graphics, or even complex logos. The print resolution is within the highest standards and the ink bonds well with the fabric, making the designs sharp and clear.

Vinyl printing: When it comes to printing logos, text, and simple shapes, vinyl printing is unparalleled. Single color designs as well as multi-color designs that use different layers of vinyl will look exceptional. On the other hand, complex, high-detail artwork cannot be accomplished with vinyl printing in comparison to DTF prints which are much more versatile.

2.Material Compatibility

DTF Printer for Shirts: DTF printing works on a wide range of materials, including cotton, polyester, and blended fabrics. This gives it an edge over other methods like sublimation printing, which requires polyester fabrics.

Vinyl Printer for Shirts: Vinyl printing works well on cotton and polyester but may not adhere as effectively to certain fabrics, such as nylon or spandex. However, vinyl is known for its ability to adhere to a wide variety of materials, including leather and canvas.

3.Durability

DTF Printing: The print DTF’s durability is remarkable. After the ink is transferred to the fabric, it is effectively fused with the fabric, rendering it impervious to fading, cracking, or peeling, even after multiple washes.

Vinyl Printing: In a manner similar to DTF prints, vinyl prints are quite durable and can survive frequent washing without peeling or fading, but the longevity of vinyl printing can differ based on the type of vinyl used and the application process.

4. Ease of Use

DTF Printer for Beginners: The DTF printer is quite user-friendly. Learning how to operate a DTF printer, especially one like the Procolored DTF printer, which requires minimal setup, is straightforward and quick, making it an ideal choice for those new to the field.

Vinyl Printer for Small Business: Like DTF printing, vinyl printing is simple. Compared to DTF printing, less technical knowledge is necessary with vinyl cutters and heat presses. However, for multi-color designs, time consuming layers of cut vinyl for each color added must be formed.

5. Cost and Investment

DTF Printer Price: While the initial investment for a DTF printing machine might be higher than for a vinyl cutter, the cost per print is lower in the long run, especially for large volumes. Additionally, DTF printers are versatile and can be used to print on a wide range of fabrics, making them a good investment for businesses looking to expand their offerings.

Vinyl Printer: Vinyl printers generally have a lower upfront cost than DTF printers, and the materials (vinyl sheets) are relatively inexpensive. However, for multi-color designs, you will need a separate sheet of vinyl for each color, which can add up over time.

6. Speed of Production

DTF Printing: With DTF printing, production happens faster, especially for prints with multiple colors, because it does not need pre-separation. Once the patterns have been printed, heat pressing them onto the fabric right away is quick and perfect for big orders.

Vinyl Printing: If you use more colors in your design, vinyl printing can be a lot slower. The vinyl cutting process and heat pressing each layer of vinyl can take time, which may make vinyl printing less efficient for large orders.

7. Setup and Maintenance

DTF Printer: Regular cleaning and maintenance are essential to keep the printer in good working order, but overall, DTF printing requires less manual effort than vinyl printing.

Vinyl Printer: Vinyl printers require more manual intervention, especially when cutting multi-layer designs. You’ll need to maintain your vinyl cutter, heat press, and ensure your vinyl sheets are properly stored to prevent waste or damage.

Which is Better for You?

Both DTF printing and vinyl printing have their pros and cons, and the choice depends on your business needs, design complexity, and material preferences. If you want to print detailed, full-color designs on a variety of fabrics, DTF printing is the clear winner.

The Procolored DTF printer offers an excellent entry point for small businesses looking for quality prints and ease of use.

On the other hand, when you want to make simple designs like logos or text, vinyl printing might be your best choice.It’s durable, cost-effective, and works well for smaller batches or more personalized projects.

For those in the custom apparel industry, understanding the DTF printer vs vinyl printer debate will help you make an informed decision on what’s best for your business.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!