Table of Contents

What is DTG Printing?

Direct-to-garment (DTG) printing is a method of printing digitally-created designs directly onto textiles. Whereas screen printing transfers ink through a mesh stencil, DTG printing uses injket technology to apply water-based ink directly into the garment.

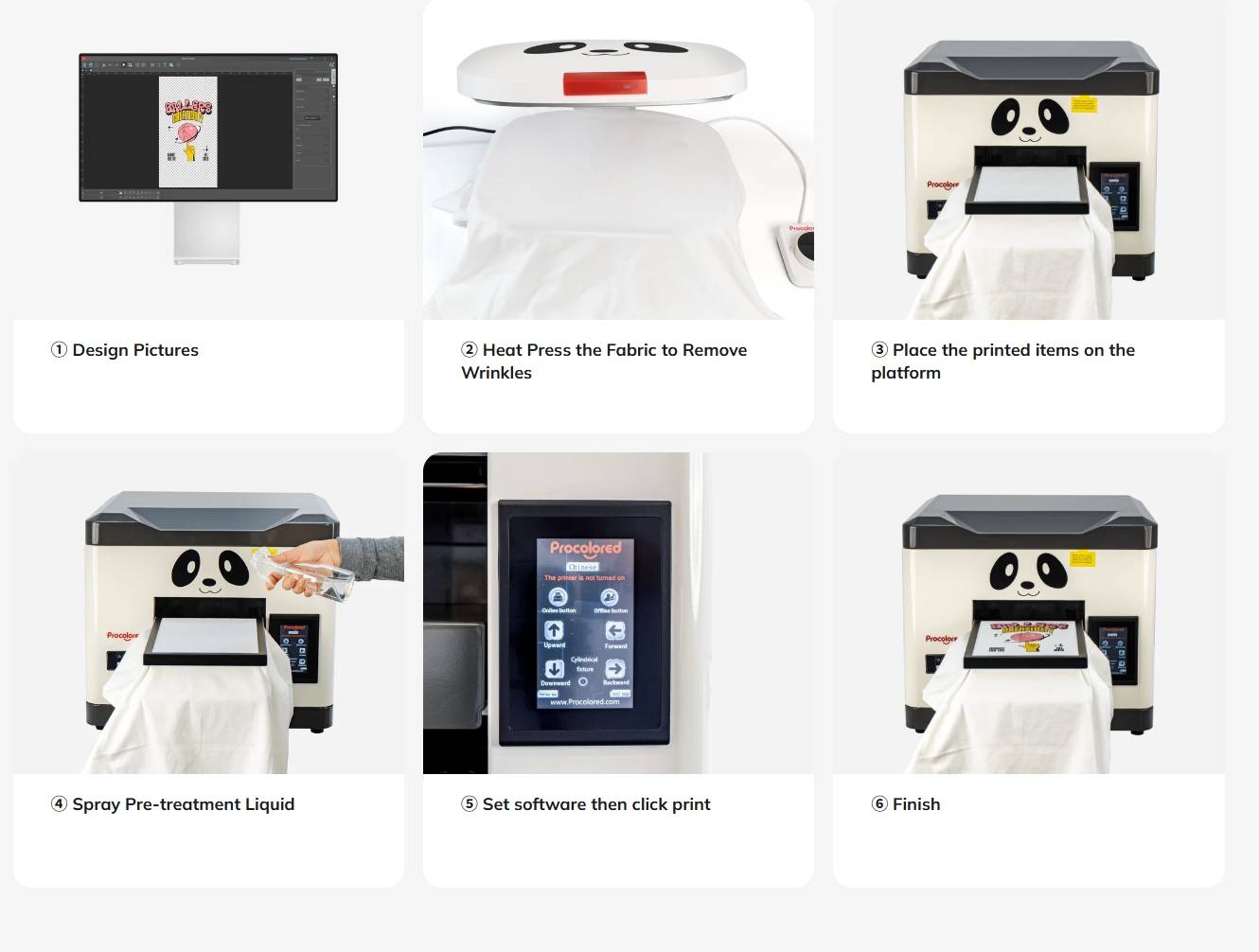

To use a DTG printer, you’ll have to follow a few steps:

1. Use a heat press to get rid of wrinkles and smooth out the fabric before printing.

2. Load the garment onto a printing platen.

3. Pre-treat the fabric ahead of time in order to allow the ink to absorb correctly.

4. Print water-based ink directly onto the pre-treated area of the garment.

5. Remove it from the platen and use a dryer to ensure the ink adheres correctly and to evaporate the pretreatment.

DTG printing is typically best for natural materials that can easily absorb the ink such as cotton or bamboo. The lack of setup time and low production costs make it well-suited to smaller businesses that have lesser volumes of product to print. One drawback, however, is that darker shirts will require more white ink and pretreatment, making them more expensive to produce.

DTG Printing Cost Breakdown

The first factor in the price of DTG printing is the cost of equipment. You’ll need a high-quality DTG printer like the Procolored A3 Pro DTG Printer, which runs for about $5,999. You’ll also need a heat press, which can cost between $300-$1,500.

To calculate the DTG printing cost per shirt, you’ll have to consider the following factors:

● Pretreatment solution: ~$1.2

● Ink: ~$0.9

● Total cost: $2.1 per shirt (not including the cost of the shirt itself).

What Is DTF Printing?

Direct-to-film (DTF) printing is a method of printing on textiles that involves first printing on a special transfer film before applying the design to a garment using a heat press. Unlike direct-to-garment printing, DTF printing can work on a variety of materials including denim, polyester, nylon, and leather.

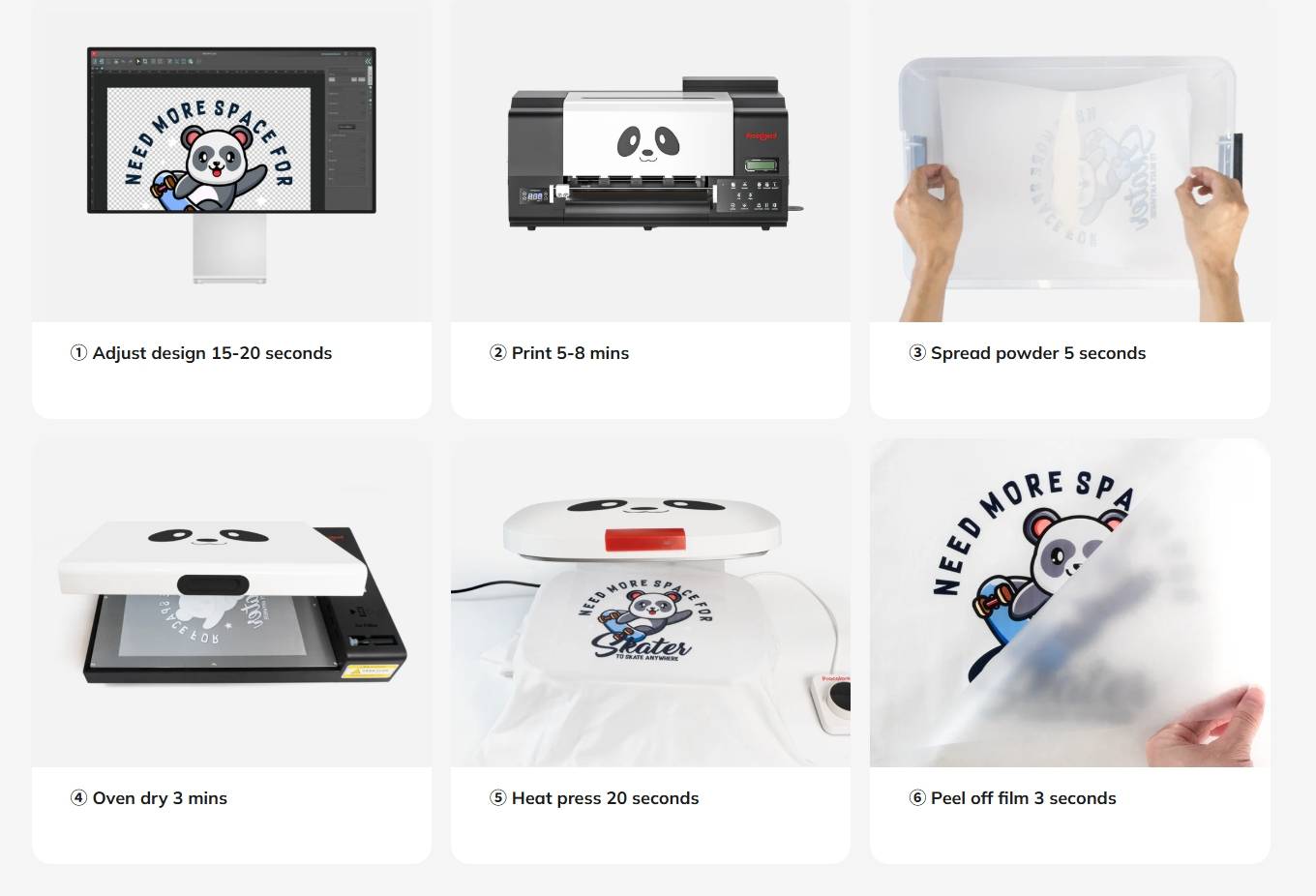

To use a DTF printer, you’ll go through the following steps:

1. Print your design onto a transfer.

2. Dust the back of the transfer with a special powdered adhesive, shaking off any excess adhesive.

3. Cure the adhesive with a curing oven or heat press.

4. Apply the transfer to the garment using the heat press.

5. Peel back the film and give the garment a final press using a pressing cloth to finish adhering the transfer.

DTF printing is well-liked for its exceptional color accuracy, detail, and durability. It also has quite low production costs as well as the ability to print on both dark and light garments.

DTF Printing Cost Breakdown

The equipment you’ll need for DTF printing will include a high-quality printer like the Procolored F13 Pro, which runs for about $5,199. You’ll also need an oven and heat press, which you can obtain for around an additional $848.

The DTF printing cost per shirt will take into account the following factors:

● DTF film: ~$0.8

● Adhesive powder: ~$0.3

● Ink: $0.9

● Total cost: $2 per shirt

DTG Printing Vs. DTF Printing: Which Is Right For You?

Both DTG and DTF printing have their own unique pros and cons. Here’s what to look at to decide which is right for you:

Print Quality/Durability

DTG printing is good at printing colorful designs, although the designs don’t appear quite as vibrant when printed on darker garments. Prints will last a long time, although the color may lose its vibrancy after the garment has been washed a number of times.

DTF printing creates colorful designs on any kind of fabric, giving you more vibrant colors than DTG printed designs. The print will be slightly thicker than DTG printed designs, but it should wear in once the garment has been washed several times. DTF printed designs are also resistant to cracking, allowing you to wash the design in cold/warm water without affecting the color.

Choice of Fabric

Because the ink struggles to bind with synthetic fabrics, DTG printing is limited to natural fabrics such as cotton, linen, or bamboo. It’s also better suited to lighter garments, as it is more costly to print on dark or black fabrics due to the need for the white ink base.

DTF printing can be used on almost any kind of fabric, from natural ones like cotton or linen to more exotic fabrics like nylon or leather. Because it doesn’t apply the ink directly to the garment, it can also be printed on fabrics of all colors without affecting the color vibrancy in any way.

Quantity

DTG shines when you’re trying to fulfill smaller batches of orders while keeping things cost-effective. If you just want to print one or two of a certain design, then a DTG printer will allow you to print without losing profitability.

DTF printing is better suited for printing larger batches, as the cost of production falls the more shirts you print. By placing bulk orders, you can lower the cost of production significantly per shirt.

Where To Find The Best DTG And DTF Printers

The key to making money with a printing business involves a reliable, cost-effective t-shirt printer. Whether you’re looking for a DTG or a DTF printer, Procolored offers some of the best t-shirt printers on the market. The Procolored A3 Pro DTG printer is easy-to-use and beginner friendly, with a touchscreen control panel that allows for immediate operations. It relies on such features as an absorption filtration system, printhead auto-cleaning, and automatic white ink circulation to keep the printer clean, protected, and free from clogs.

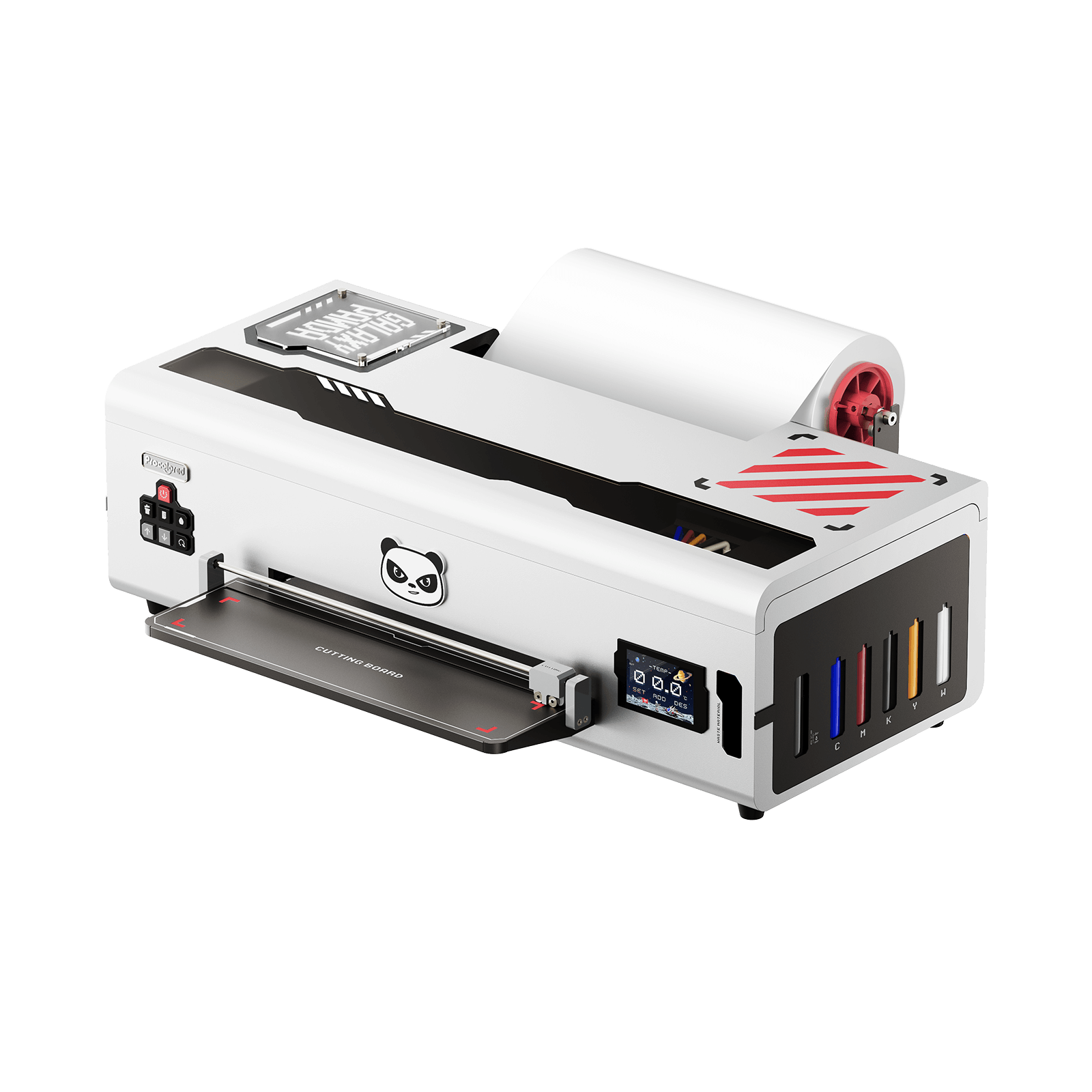

The Procolored F13 Pro Panda DTF Printer is an advanced, user-friendly DTF printer that uses dual print heads to produce professional-looking prints at high speed. Great for small businesses, Procolored’s DTF printers feature an auto-cleaning printhead that reduces clogging and requires less maintenance, allowing you to focus on printing without interruption.

When comparing DTG vs DTF printing cost, DTF printing stands out as the better choice for printing larger batches or on darker/synthetic fabrics. If you’re ready to take the plunge, the Procolored DTF printer offers an excellent balance of quality, affordability, and user-friendliness. Not only is it a great DTF printer for beginners, but it’s a great DTF printer for small businesses looking to turn a profit right away.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!