Table of Contents

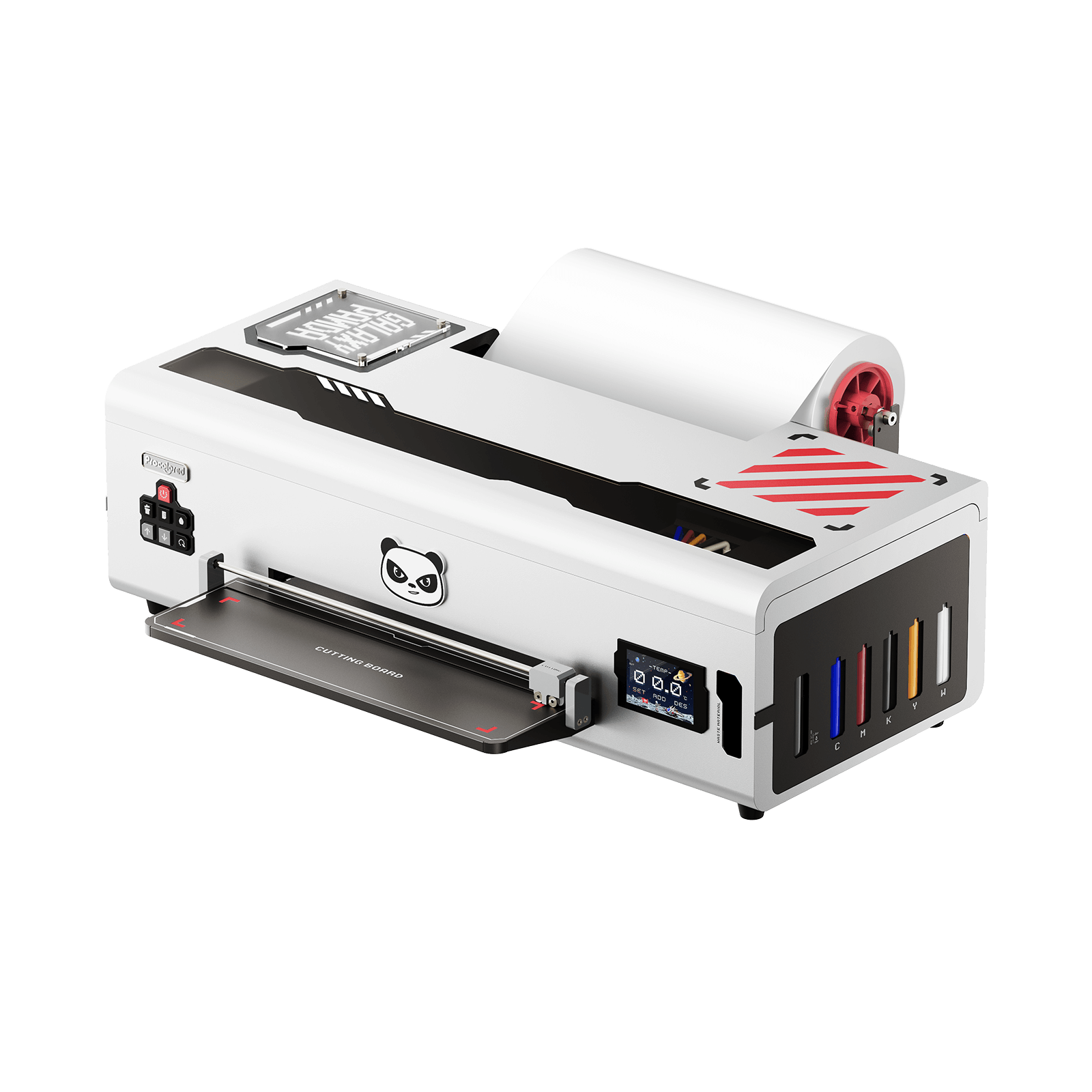

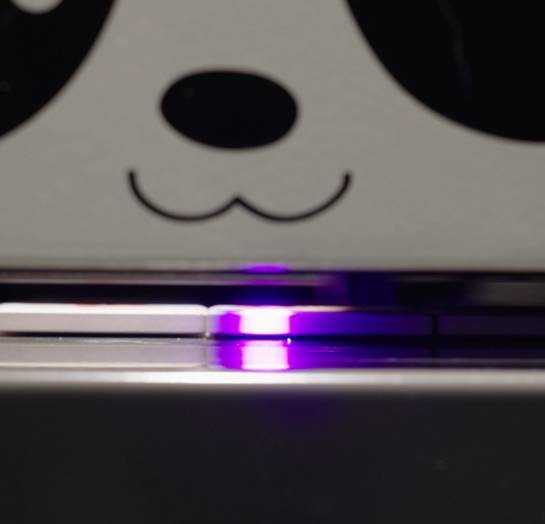

How UV Printing Works?

Materials UV Printers Can Print On

A. Plastics

B. Glass

C. Metals

D. Wood

E. Ceramics & Porcelain

F. Leather and PU Leather

G. Paper & Cardboard

H. Fabrics (Limited Compatibility)

3D Objects and Unusual Surfaces

A. Items that are Curved and Cylindrical

B. Small Promotional Items

C. Specialty Surfaces and Uncommon Materials

Why Does This Matters for You?

Industry Use Cases

A. Advertising and Signage

B. Interior Design & Architecture

C. Gifts and Personalization

D. Prototypes of Packaging

E. Industrial and Electronics

Limitations & Considerations

Additional Surface Preparation May Be Required

Size Is Important

Not Appropriate For Fabrics Or Stretchy Materials

Always Test Before Mass Production

Conclusion

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!