Table of Contents

Understanding the “Plastic Feel” Concern

The Comfort Test: How Different Prints Feel on Fabric

Quick Comparison

DTG clearly wins for softness, while DTF printing offers versatility, and vinyl lags behind in comfort.

When DTG Can Feel Plastic-Like

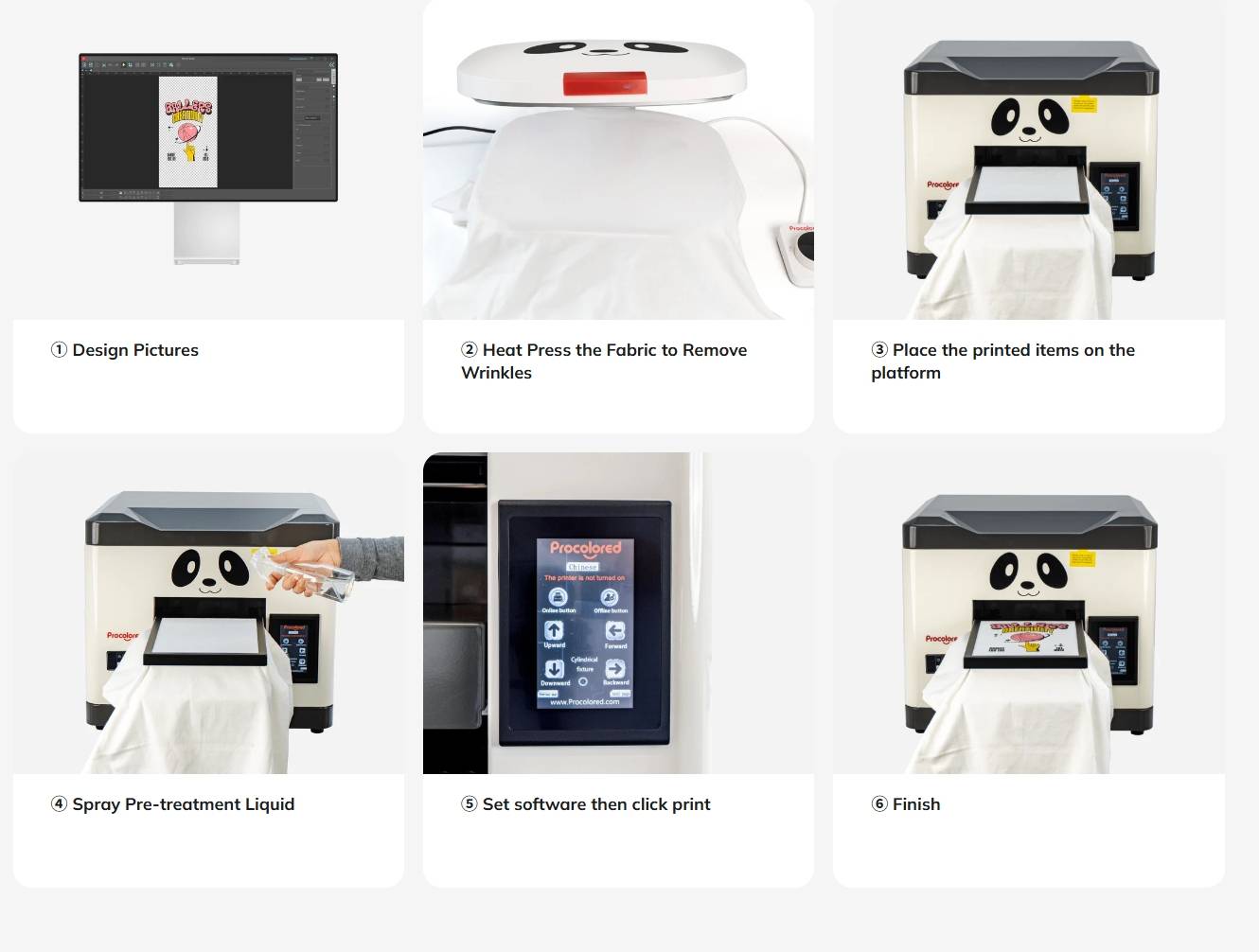

The Role of Pretreatment

How Procolored Solves the “Plastic Feel” Problem

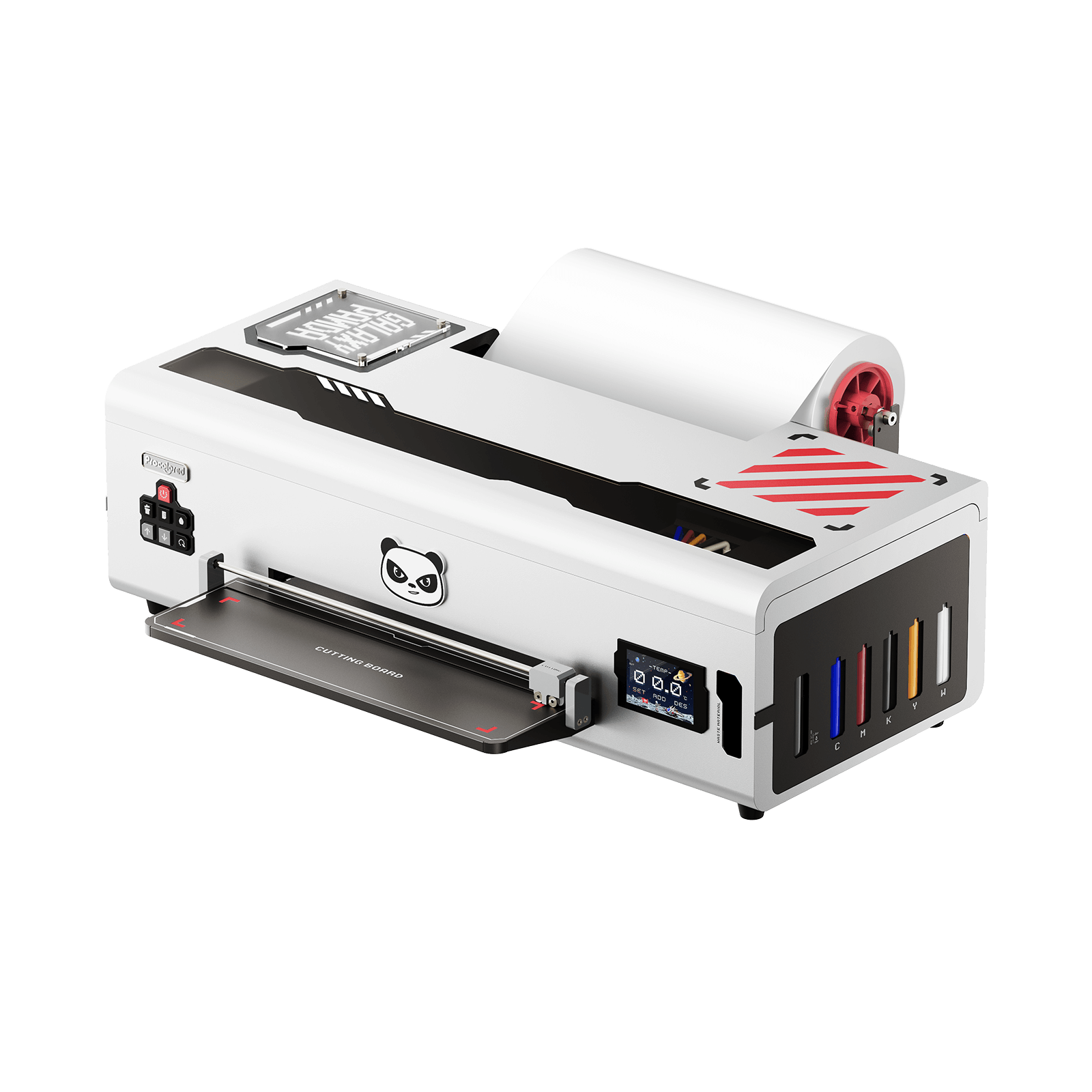

Comparing DTG vs. DTF Printers

Customer Experience: What People Say

Tips for Achieving the Softest Prints

Conclusion

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!