Table of Contents

Common DTF Print Sizes for Shirts

Full Front or Back Prints

Chest or Left Pocket Logo

Mid-sized Center Prints

Sleeve Prints

Neck Tag Prints (Inside label modification)

Factors Influencing DTF Print Size

1. Garment Size (S–XXXL)

2. Print Head and Film Size Limits

3. Heat Press Platen Dimension

4. Design Specifics

DTF Sheet Layout & Gang Sheet Strategy

What Is a Gang Sheet?

Choosing the Right Print Size

Focus on Design

Focus on Wearer

Garment Type

Mockups & Testing

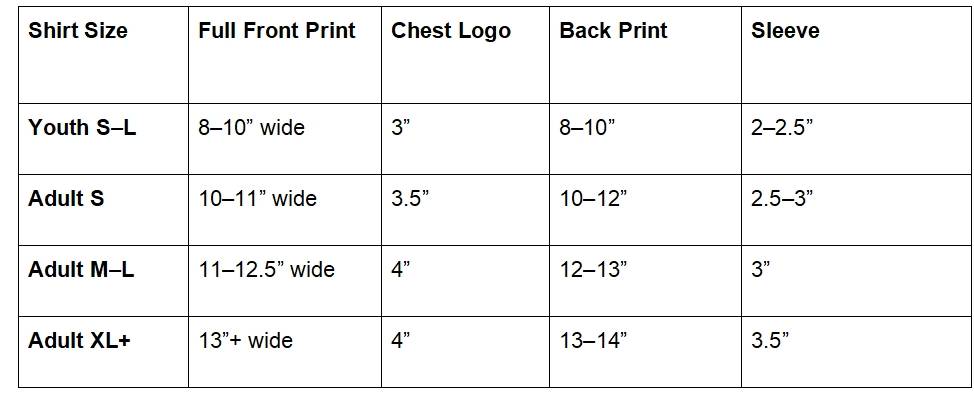

DTF Print Sizes Chart

Tips for Scaling and Positioning

Keep the Aspect Ratio

Try It on a Template First

Use Positioning Tools

Conclusion

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!