Table of Contents

In the printing industry, most people use DTF(Direct to Film) printing and Inkjet printing. Although both give excellent results for prints, they are intended for different jobs and each has its own benefits depending on what is being done.

If you work in the custom printing business or are interested in starting out, knowing the differences between DTF(Direct to Film) and Inkjet will guide your decision. In this article, we’ll explore both technologies, their pros and cons, and how they compare, especially in applications like t-shirt printing, garment customization, and more.

What is DTF Printing?

DTF means Direct to Film, meaning a design is imprinted onto a unique film and later moved onto different materials using heat. Many industries, especially custom apparel, are adopting this technique because it is versatile, produces clear prints and produces sturdy results. By using DTF printing, you can produce brightly colored patterns on fabrics including cotton, polyester and compounds.

Key Components of DTF Printing

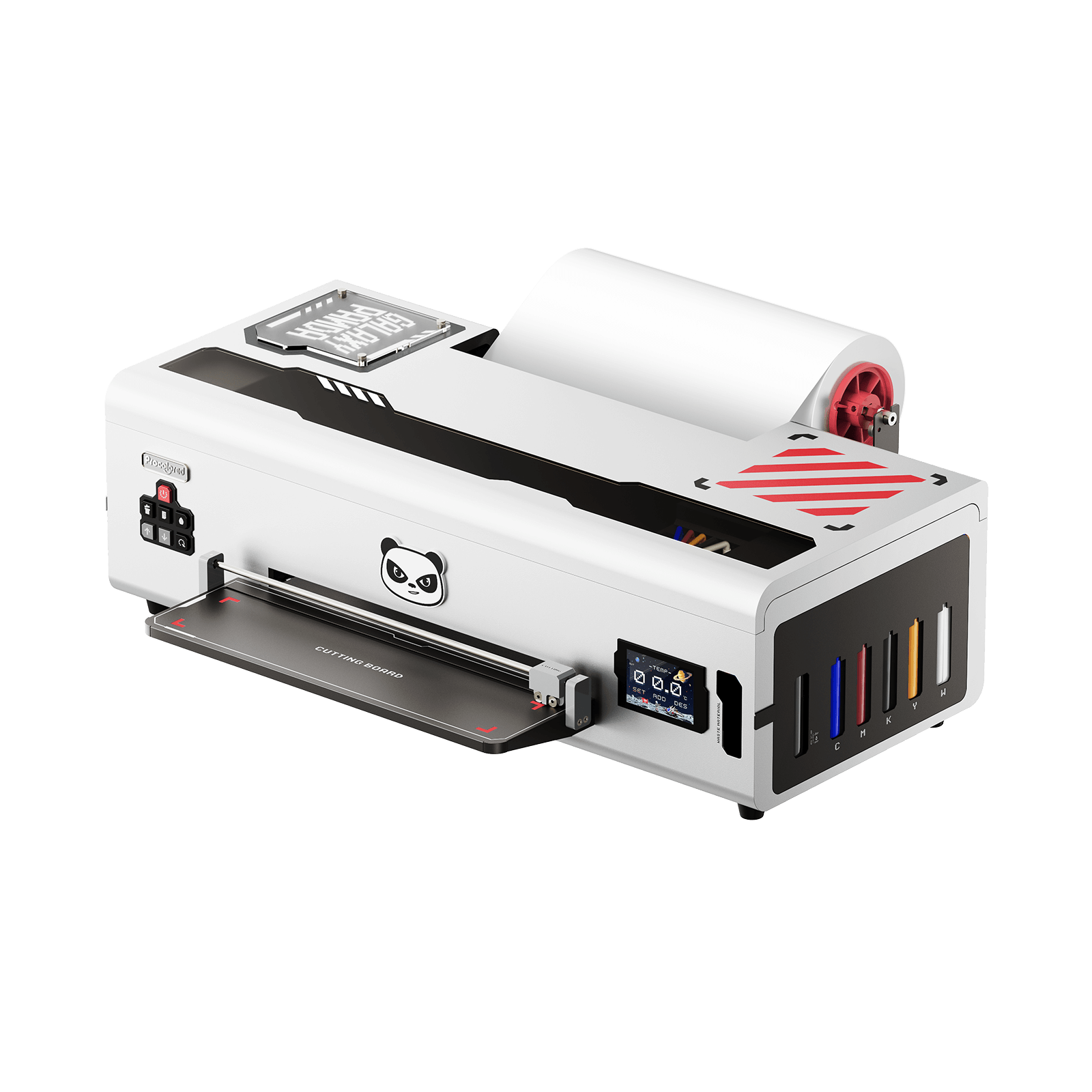

DTF Printer: A printer that uses the DTF process is responsible for printing your design onto the film. Special printheads on these printers are designed for producing high-quality and long-lasting prints.

DTF Film: It allows your design to enter the printing process. First, the ink is put onto the film and then it is heat-pressed onto the garment.

Adhesive Powder: An adhesive powder is applied to the design after it is printed on the DTF film. The powder helps hold the ink in place while applying the design to the fabric.

Heat Press: With a heat press, the design is transferred from the print to the fabric, ensuring it holds well on the material.

Advantages of DTF Printing

Versatility: DTF printing stands out because it can be used on a broad selection of fabrics. You can use DTF printing on almost any kind of fabric, including cotton, polyester and blends.

High Quality and Detail: DTF printing provides crisp, bright designs, so is best suited for detailed designs, colorful prints and photographs.

Durability: Durable prints are a result of DTF ink technology. Unlike a few other printing types, DTF prints retain their appearance and do not separate, crack or fade after washing.

What is Inkjet Printing?

Inkjet printing is a time-tested method used to create high-quality prints. It does this by releasing small drops of ink onto the paper or fabric from the microscopic holes in the printhead. Most people use inkjet printers to print on paper, but there are also inkjet printers designed for textiles and t-shirts.

Key Components of Inkjet Printing

Inkjet Printer: A typical inkjet printer uses liquid ink to to create images on materials like paper, fabric, plastic and vinyl. It is capable of full-color printing and is famous for its accurate and fine results, mainly in photographs and prints of artwork.

Ink: Inkjet printers use liquid ink (dye-based or pigment-based) to to color the surface of whatever they are printing on. The image is absorbed into the paper or fabric which results in sharp and bright colors.

Substrate: While regular inkjet printers use paper, by using different inks and treatments on fabric, they can be used to print on shirts.

Advantages of Inkjet Printing

Ease of Use: Printing with an inkjet is simple and these printers are often used both at home and in the office. They are easy on the wallet and are useful for a range of tasks, for example, printing photos, papers and more.

High-Resolution Prints: Inkjet printers, just like DTF printing, excel at providing detailed prints on images and graphics. These papers produce great results for both photos and detailed artwork.

Lower Initial Investment: For individuals or companies new to custom printing, inkjet printers are often a much more affordable option than DTF printers.

DTF Printer vs Inkjet Printer: A Detailed Comparison

Having looked into both DTF and inkjet printing, it is now time to see how they differ when it comes to print quality, how durable they are, suitability of materials and costs

1. Print Quality and Detail

DTF Printer: With DTF printing, detailed full-color printouts are achieved at a very high level of quality. Since it handles many colors and shades, CMYK is great for detailed drawings, photos and artwork with multiple colors. Moreover, the transfers made from the plates ensure the results will stay vibrant and last a long time.

Inkjet Printer: Inkjet printers are recognized for providing excellent resolution that showcases small details in photos or drawings very well. Still, inkjet printers might not achieve the same quality of bright and durable prints on fabric as DTF printers do. Sometimes, inkjet prints on fabric lose their color after being washed repeatedly.

2.Material Compatibility

DTF Printer for Shirts: A key plus of DTF printers is that they work on many different suit materials, including only cotton, polyester and some blended materials. That’s why DTF printing is perfect for businesses that make custom apparel, since they need flexibility in using different fabrics.

Shirt Inkjet Printer: T-shirt inkjet printers do print on fabric but you need a certain kind of dye (e.g., pigment) and the shirt has to be pre-treated so the design stays in place. Printing with inkjet machines isn’t as versatile across fabrics as printing with DTF printers and sometimes the results are not the same.

3.Durability

DTF Prints: Prints produced with a DTF printer are famous for being extremely durable. When the design is applied to the fabric, it becomes firmly secured and can handle lots of washing without losing its appearance.

Inkjet Prints: Though both are usable on paper, when printed on fabric, inkjet prints will not last as long as DTF prints. After washing, the ink may fade more quickly and will not hold up to much rough handling.

4. Ease of Use and Setup

DTF Printer for Beginners: The process of DTF printing is easy, still, you need certain machines to print such as a DTF transfer printer, DTF film and a heat press. DTF printing equipment can be complex, but if you start with a printer like Procolored's, you will find it easier to set up.

Inkjet Printer for Small Business: Setting up an inkjet printer and learning to use it is simplified for beginners. It is possible that for fabric printing, you need to have special inks and treatments. For people starting simple print jobs, inkjet printing tends to be the better choice.

5. Cost of Operation

DTF Printer Price: The cost of a DTF printer is usually more than an inkjet printer at the start. Still, they turn out to be more economical in terms of printing costs if a business requires high-quality items frequently. Furthermore, DTF printing works well with multi-color designs so you can complete them faster and at a lower cost.

Inkjet Printer Price: Inkjet printers are generally cheaper to buy, especially for small-scale or home-based operations. However, when it comes to printing on fabric, the costs can add up due to the need for specialty inks, treatments, and transfer paper.

6. Speed of Production

DTF Printer for Small Business: DTF printing is faster for large runs, especially when printing complex designs. Once the design is printed on the DTF film, it can be quickly transferred to the fabric with a heat press. This makes DTF printing ideal for businesses that require quick turnaround times.

Inkjet Printer: Inkjet printers are slower and noticeably so when working with fabrics. Don’t forget that the process requires you to wash and dry the fabric properly and put the transfer design on at the correct temperature.

Best DTF Printer for Small Business

Selecting the right printer matters a lot for small businesses wanting to try custom tshirt printer. If you run a small business, the Procolored DTF printer is an ideal choice since it performs well, prints beautifully and is quick to set up. Because of the siphon system, Wide Format Printers waste less ink and print consistently.

Large businesses that need to make many big prints will find that A3 DTF printers are ideal. If you’re buying a commercial DTF printer, go for models that can fulfill the workload and offer the advanced features needed for top-quality printouts.

Which Printer is Right for You?

The choice between a DTF printer and an inkjet printer will vary depending on what your business needs and what types of projects you run. Business owners who want prime, tough prints on numerous materials, mainly for t-shirts and custom clothes, should choose DTF printing. Commonly, inkjet printing performance suffices, although it does not handle complex projects and enormous fabric runs.

If your company is small or you are starting out in the custom printing industry, a DTF printer like the Procolored DTF printer will offer you the flexibility, good printing quality and durability that your customers expect.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!