Table of Contents

Why Sublimation? And Not Traditional Sock Printing?

What You’ll Need – The Sock Printing Starter Pack

Alright, before you start crafting out those sublimated socks, you gotta have your gear lined up.. Fortunately, it is not a long list, and we will guide you through the entire process. Think about it like progressing through the levels of a video game; every stage gets you closer to those sweet, pro-level sock prints.

Level 1: The Basics – Your Must-Have Materials

Level 2: Printing Supplies—The Real Magic

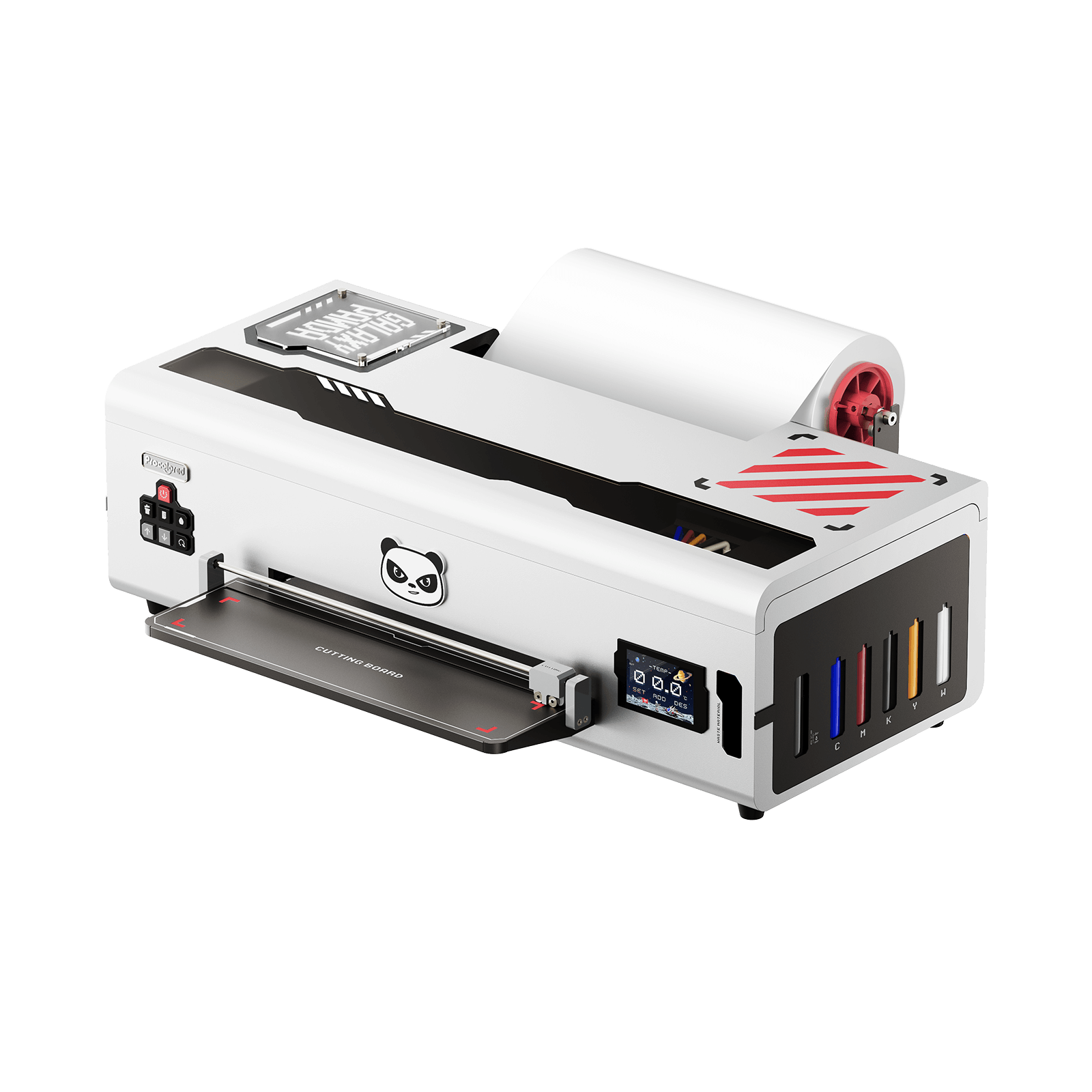

Level 3: The Game-Changer – A Procolored DTF Printer

Step-by-Step: How to Sublimate Socks

Step 1: Design Your Artwork

Step 2: Print the Design

Step 3: Prepare the Socks

Step 4: Press and Transfer

Step 5: Finishing Touch

Pro Tips for Perfect Sock Sublimation

1. All Over Templates Should Correspond to Jig and Sock Dimensions

2. Avoid Over-Saturation in High-Stretch Areas During Inking

3. Purchase High-Quality DTF Film and Ink

Scaling Beyond Socks

Maintain Uniform Designs Throughout Your Collections

Design Sets For Gifts

Make Use of Seasonal Trends and Events

Troubleshooting Common Sock Printing Issues

Print Patterns With Missing Colors?

Edges Of Design Lacking Definition?

Colors Applied Unevenly Or Has Gaps In Some Areas?

Wrap-Up: From Hobby to Hustle

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!