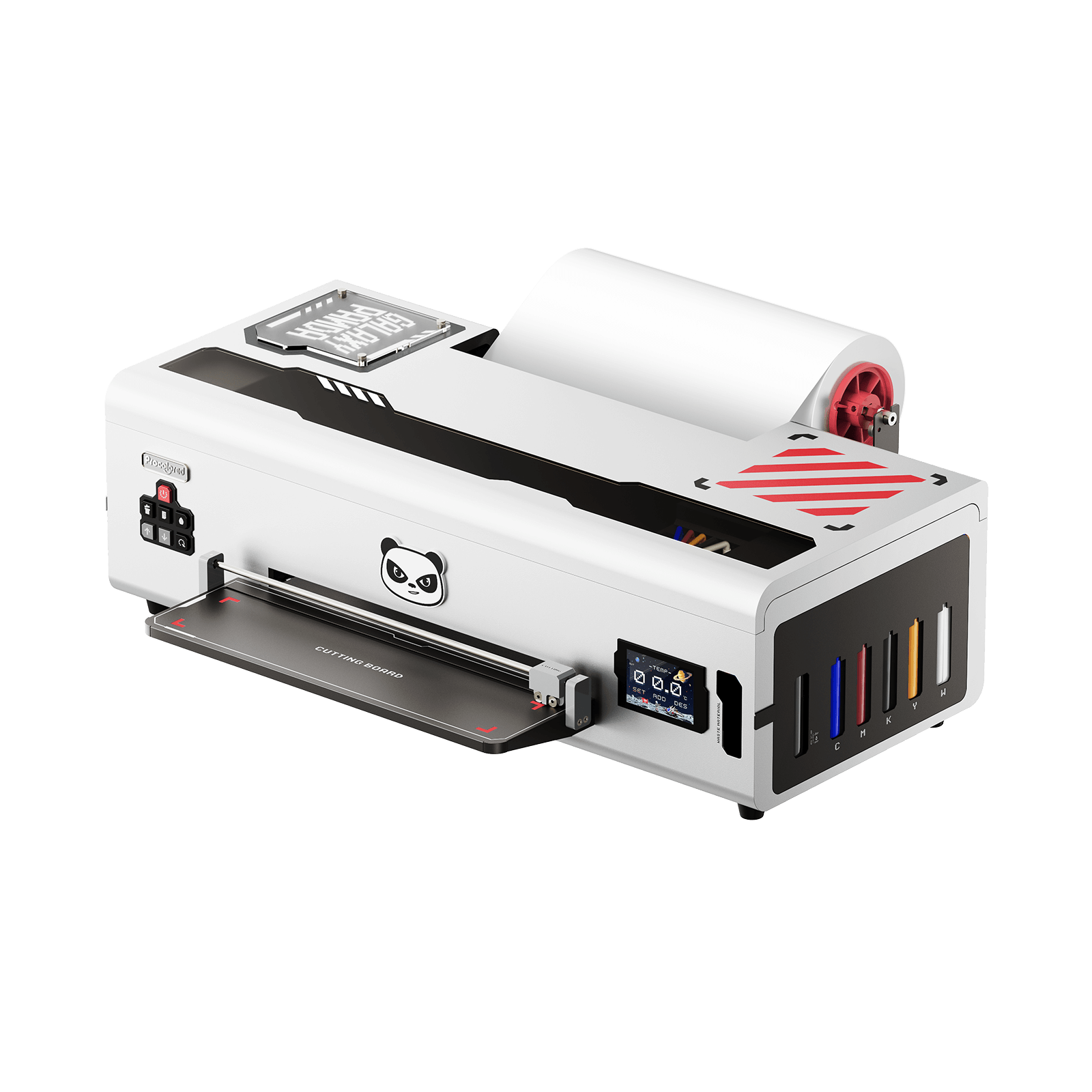

DTF Printer (Direct To Film)

DTF printer, also known as Direct-to-Film printer, uses DTF ink and PET film to deliver high-quality transfers onto a wide range of fabrics, including cotton, polyester, cotton-polyester blends, spandex, nylon, denim, canvas, and more. As a versatile printer for T-shirts and other textiles, it’s ideal for various apparel printing applications.

Looking for a reliable DTF printer to kickstart your custom T-shirt business? Procolored provides the best DTF printer collection, featuring both A4 DTF printers for beginners and A3 DTF printers for small studios. Configured with patented Procolored Siphon Circulation System, our machines provide vibrant color output and stable performance, making them the perfect printer for T-shirts across different business scales.

Start your creative journey with a Procolored DTF printer now — or explore and compare our machines to find the most suitable T-shirts printer tailored to your needs.

Filter

45 products

Collection

Find the Right DTF Printer for You

Find the Right DTF Printer for You

From entry-level models like the A3 DTF printer for beginners to high-throughput systems for apparel production, Procolored offers scalable solutions to fit every business.

From entry-level models like the A3 DTF printer for beginners to high-throughput systems for apparel production, Procolored offers scalable solutions to fit every business.

Printhead

Printhead

Printhead

Printhead

Printhead

Printhead

Printhead Config.

Printhead Config.

Printhead Config.

Printhead Config.

Printhead Config.

Printhead Config.

Print Accuracy

Print Accuracy

720*1440 DPI

(16 PASS)

Print Accuracy

Print Accuracy

Print Accuracy

1440*1400 DPI 8 Pass

Print Accuracy

1440*1400 DPI 8 Pass

Print Size

Print Size

Width: 13"(330mm)

Print Size

Print Size

Width: 13"(330mm)

Print Size

Width: 13"(330mm)

Print Size

Width: 8.2"(210mm)

Print Speed

Print Speed

Letter/A4: 7min

Print Speed

Print Speed

Letter/A4: 4.5min

Print Speed

Letter/A4: 10min

Print Speed

Letter/A4: 7min

Color Configuration

Color Configuration

CMYK+WW

Color Configuration

Color Configuration

Color Configuration

CMYK+WW

Color Configuration

CMYK+WW

Applicable System

Applicable System

Windows/Mac

Applicable System

Applicable System

Applicable System

Windows OS

Applicable System

Windows OS

Software

Software

Pro RIP

Software

Procolored Studio Lite

Software

Software

Pro Rip

Software

Pro Rip

Suitable Business Size

Suitable Business Size

350+/week

Suitable Business Size

Suitable Business Size

450+/week

Suitable Business Size

200+/week

Suitable Business Size

200+/week

Unit per Hour

Unit per Hour

8

Unit per Hour

Unit per Hour

13

Unit per Hour

6

Unit per Hour

8

Profit per Day

(5-hour Work Day)

(5-hour Work Day)

Profit per Day

$659.01

Profit per Day

Profit per Day

$1319.55

Profit per Day

$493.85

Profit per Day

$440.94

DTF Printer

DTF (Direct-to-film) printing is one common method used in T-shirt printing. To finish a direct to film transfer, the graphic will be first printed on a pre-treated film, then covered with adhesive powder, after curing and heat pressing, finally transferred onto fabrics. DTF machine prints colored inks with a white ink base, allowing its printed outputs to achieve a higher color reproduction compared to other methods such as DTG.

Besides providing the best DTF printer, Procolored also enables DTF printing on rigid objects, with UV DTF Printer.

Versatility of DTF printer

Versatility of DTF printer

T-shirt printing industry has become a larger and larger maarket with impressively speedy growth in recent years. Following this

tendency, more and more people nowadays prefer purchassing customized clothes and even begin to seek methods ofproducing

their owns. A DTF machine can be a perfect choice for thisneed of T-shirt customization.

There is no doubt that DTF printing technology has gradually ardoused attention from T-shirt print-on-demand industry with its high quality, accuracy, flexibility, and convenience. It can be used on a variety of fabrics, including cotton, polyester, blends, and even dark-colored fabrics. It's capable of printing complex, colorful and detailed designs and transferring them in durable and long-lasting quality to fabrics. Compared toother printing methods like DTG printing, it only requires relatively easier operations and lower costs, suitable for smhall businesses and startups.

There is no doubt that DTF printing technology has gradually ardoused attention from T-shirt print-on-demand industry with its high quality, accuracy, flexibility, and convenience. It can be used on a variety of fabrics, including cotton, polyester, blends, and even dark-colored fabrics. It's capable of printing complex, colorful and detailed designs and transferring them in durable and long-lasting quality to fabrics. Compared toother printing methods like DTG printing, it only requires relatively easier operations and lower costs, suitable for smhall businesses and startups.

T-shirt printing industry has become a larger and larger maarket with impressively speedy growth in recent years. Following this

tendency, more and more people nowadays prefer purchassing customized clothes and even begin to seek methods ofproducing

their owns. A DTF machine can be a perfect choice for thisneed of T-shirt customization.

There is no doubt that DTF printing technology has gradually ardoused attention from T-shirt print-on-demand industry with its high quality, accuracy, flexibility, and convenience. It can be used on a variety of fabrics, including cotton, polyester, blends, and even dark-colored fabrics. It's capable of printing complex, colorful and detailed designs and transferring them in durable and long-lasting quality to fabrics. Compared toother printing methods like DTG printing, it only requires relatively easier operations and lower costs, suitable for smhall businesses and startups.

Other main advantages of DTF printing over DTG printing:

Higher reliability of print head to meet large-volume printingneeds

More vibrant printing colors on both light and dark-colored goarments

No fabric pre-treatment required

T-shirt DTF Printing Procedure

T-shirt DTF Printing Procedure

Image Transform

Send the print job to the DTF printer using RIP software.

Print

DTF printer prints image onto pre-treated transfer film.

Spread Powder

Cover the print with adhesive powder and melt the adhesive via a curing oven.

Heat Transfer

Transfer the design onto the garment via a heat press machine.