Nature is the New Luxury

As public awareness of recycling and sustainability keeps gradually growing, both commerce and consumers nowadays are in chase of products of natural materials.

Among them, wooden products are one of the most prevalent. Why about all the hype and how to get involved in such new trend? Scroll down to get more information.

PASSAGE SUMMARY

1. Why Wood Printing?

1.1 Durability of wood

There’s evidence suggesting that the use of wood was integral to human life as far back as the Lower Paleolithic era, approximately 2 million years ago. Since then till today, wood as a natural material has been widely applied in human lives and productions - besides being used as firewood, they are afterwards be made into instruments, furniture or house constructions, etc.

Wood plays such critical role in human history for a good reason: it is made of long, thin and strong cells which provides significant resistance against great forces caused by wind, bad weather or natural disasters.

1.2 Public preference on sustainable materials

Sustainability has been top of mind for global commerce for many years. With the hype of environment protection and recycled resources growing, producers and consumers are both becoming more and more conscientious about how the products will impact the health of our ecosystem and planet for the years to come.

Wood perfectly meets all the needs of sustainability:

Renewable resource - Tree, where wood comes from, is a renewable resource. With appropriate climate, in-time reforesting and sustainable frequency of logging, trees and forests can be cultivated again thus providing abundant resources for wood.

Greener disposal process - From original tree branches or trunks, to the finished products as lumbers, corks or blocks, there are less preservatives and treatments being used during the disposal process of wood, compared to other disposals of materials like steal or concrete.

Eco-friendly biodegradability - Wood can biodegrade or be composted at the end of its service life, returning nutrients back to the soil and achieving a complete ecological loop.

1.3 Wide application

Wood first was only used to make larger products like construction components, furniture, tools or kitchenware. Only starting from the past decades, it has also been applied to smaller items especially personal presents or decors, like wooden phone case, sculpture, photo frame, keychain, coaster, mobile phone stand and so forth.

And along with great development of technology, there’s a new trend being performed on such small wooden items -printing on wood. Think about all the wooden items around you, and imagine that you can directly print any graphics or texts on them, like printing wooden blocks(for example, Scrabble), wooden chessmen, or wooden shop signs placed at the shop entrance.

Supported by developing technology, numerous printing techniques have gradually emerged. In the following passage, let's delve deeply into the top 4 ones of them.

2. The Top 4 Wood Printing Techniques

2.1 Vinyl printing

picture from https://www.cutcutcraft.com/weeding-vinyl-how-to-weed-vinyl-words/

Vinyl printing, or more specifically, we say vinyl cutting, can present vibrant colors and elaborate detailed graphics on both fabrics and solid materials like wood, but requires specific equipment like vinyl cutter and heat press.

In vinyl printing, the graphics silhouette will be outlined via vinyl cutter on vinyl sheet (with limited optional colors). To get the real desired graphic that we want, we need to use a weeding hook to remove the unwanted vinyl. After being weeded , the graphic should be applied on the sanded wooden surface then be cured by heat press.

Sounds like the same process of attaching vinyl printing on fabrics? Yet there are still slight differences: wood better be cleaned and sanded to achieve better printing presentation; the heat press time better be longer than the one applied in fabric printing, to ensure the complete bonding between vinyl printing and wood grain.

2.2 Screen printing

picture from https://tshirtplus.com.au/blog/screen-print-guide/

Screen printing, also called silk screening, is probably more known as a printing method for fabrics to most people. But in fact it is another effective way to transfer image to wood.

The printing processes of screen printing on both fabrics and wood are mostly similar - they both apply stencil (or screen) and squeegee to complete the printing. The graphic silhouette first should be made on a stencil (by using photosensitive emulsion and positive film, then being exposed to light). Then colorful inks (better acrylic or oil-based inks for wood printing) will be applied and be pulled by a squeegee, going through the stencil and onto the wooden surface.

But for wood printing, it’s suggested to sand the wood first before the printing, also to apply harder pressure during the printing and to leave the wood prints air-dried after the printing.

2.3 White toner printing

picture from https://stoneridgegraphics.com/white-toner-printing

White toner is a specialized form of digital printing that uses a unique type of laser printer equipped with both color inks and white ink. To achieve printings on wood, a heat press or an iron is also needed.

Unlike vinyl printing, white toner printer actually prints out inks and graphics on the paper but not just the silhouette. This printing output can directly be pasted on clean and sanded wooden surface and then be cured by a heat press or an iron.

White toner printing frees the users from tedious vinyl weeding and can also achieve bold and vibrant colors.

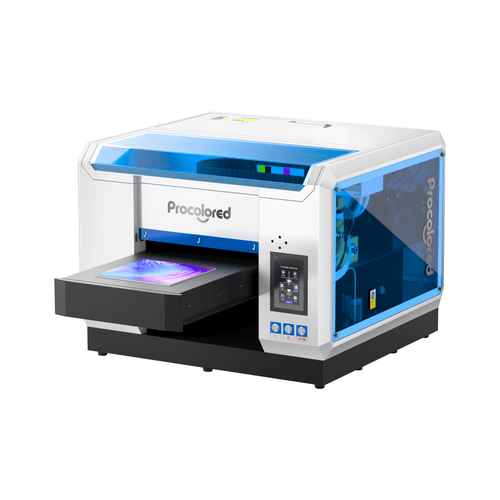

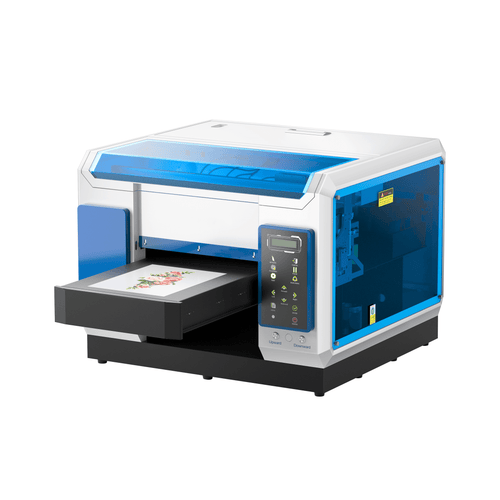

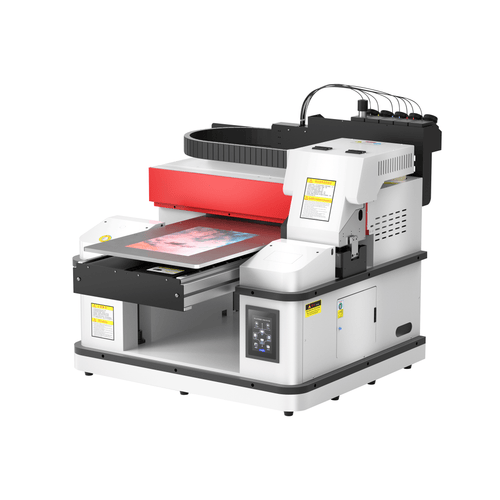

2.4 UV printing

Compared with vinyl cutter and white toner printer, UV printer can be counted as a “printer on wood” in real sense. It provides a truly hassle-free printing experience - it directly prints on solid materials and at the same time cures the inks via built-in UV lights; moreover, no more heat press or air-drying process will be needed after the printing.

Compared with screen printing, UV printing is more eco-friendly. UV printing won’t emit VOCs (volatile organic compounds) as screen printing does during the entire printing process, thus creating a more friendly and comfortable working environment.

Among the above 4 printing methods, UV printing exhibits the strongest durability. UV printing can be preserved for more than 3 years (if placed indoor), safe from scratching, water and abrasion.

Using UV inks and UV printers of higher quality can to most extend elevate the printing output and prolong the printing longevity. So of course come to Procolored! We provide UV printers with multiple printable sizes and print head configuration; we equip our UV printers with infrared automatic height sensors; and most of our products are designed with advanced cooling system to ensure of a more stable machine working status.

Visit our catalogue and give wood printing a try!

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!