Table of Contents

The Science Behind DTF Transfer Durability

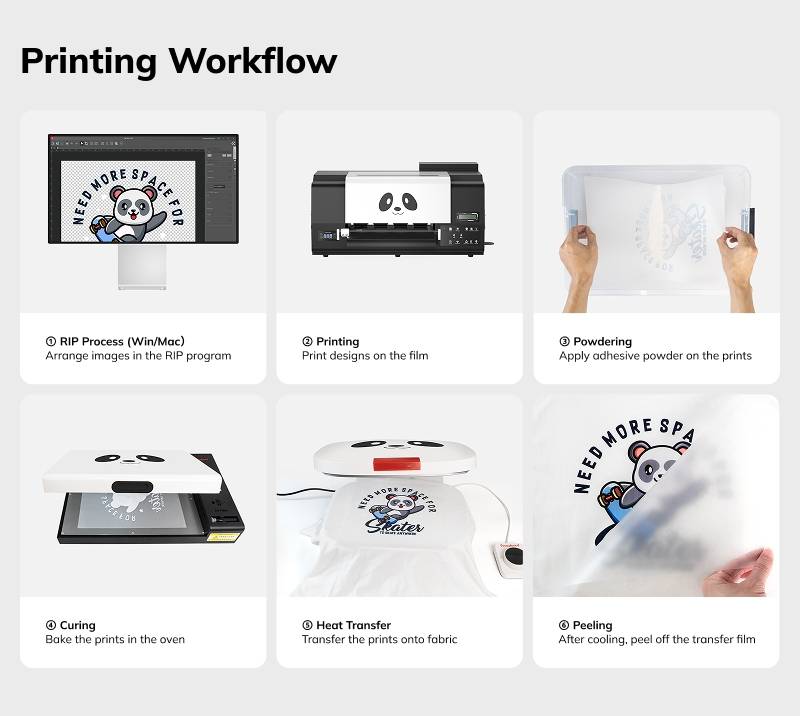

A. How DTF Transfers Work (Simplified)

B. Why Cracking or Flaking Happens

Top 7 Reasons Your DTF Prints Are Cracking or Flaking

1. Incorrect Curing Temperature or Time

2. Poor Ink Quality or Flow

3. Low-Grade or Overused PET Film

4. Bad Adhesive Powder Application

5. Poor Pressure or Uneven Heat Application

6. Incompatible fabrics

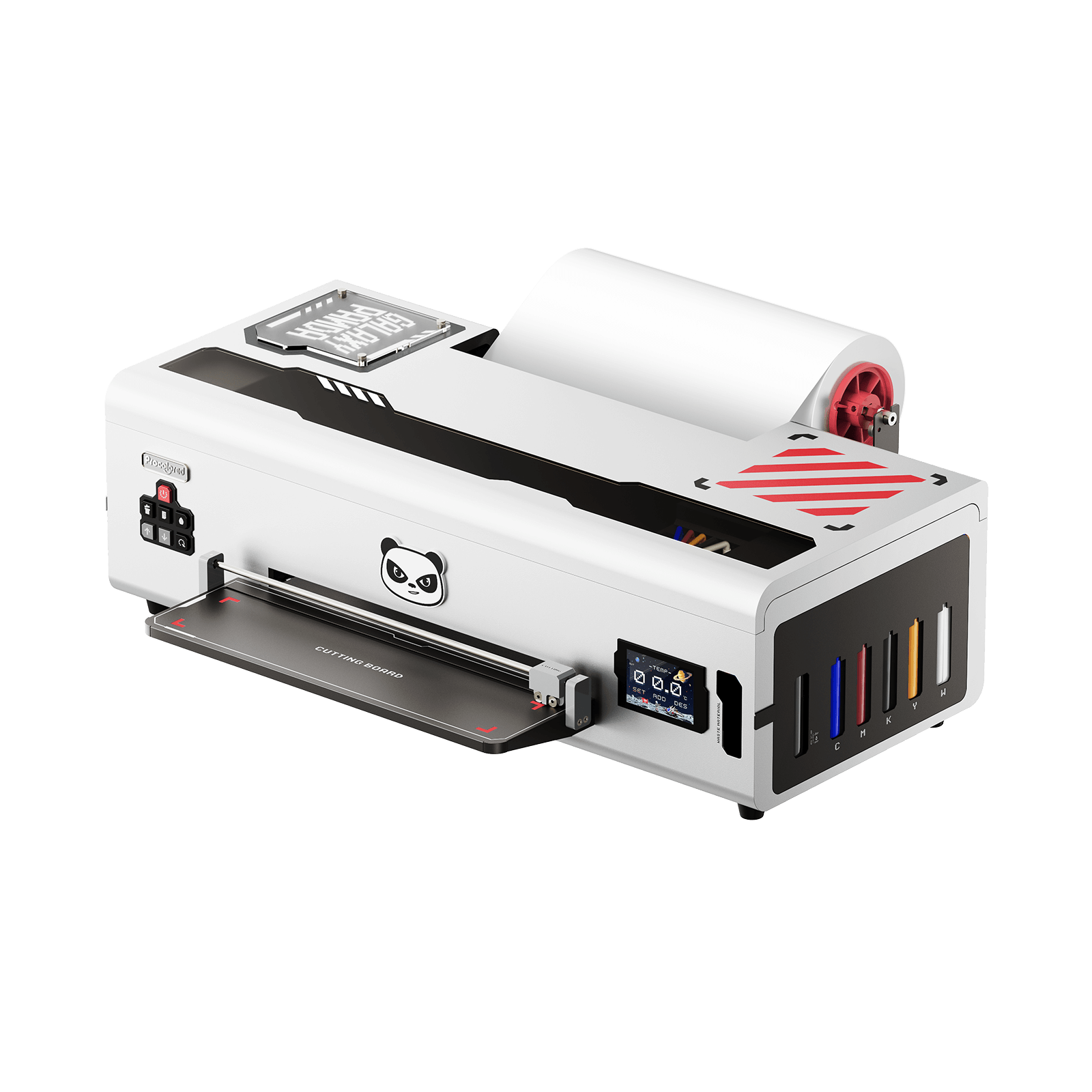

7. Low-Quality Printer Heads or Other Mechanical Issues

How to Prevent Cracks: Pro Tips That Actually Work

A. Nail the Temperature & Time

B. Don’t Skimp on Film & Powder

C. Apply Powder Evenly

D. Pre-Press Your Fabric

E. Use a Solid Heat Press

Why Procolored DTF Printers Make All the Difference

Troubleshooting: Fixing Prints That Are Already Cracked

A. Heating it with Butcher Paper

B. Try Double-Press Method

C. Swap Out Your Film Or Powder

Care Instructions for Long-Lasting DTF Prints

Final Thoughts

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

About the Author - Joyce

Joyce has worked with Procolored since the first day she joined inkjet printing career. Through continual training courses and years of working experiences, Joyce has formed a comprehensive understanding over Procolored products and a thorough knowledge of printing technologies.

Subscribe

To join our mailing list

and never miss our updates!

Subscribe

To join our mailing list

and never miss a baby update!

Subscribe

To join our mailing list

and never miss our updates!